A self-described “firearms machinist,” Dave Wilson’s name is repeated far and wide online wherever AR enthusiasts seek expert help with their builds. I’ve personally lost count of how many times I’ve seen Dave Wilson’s name mentioned in reverence, as his work and work ethic is second to none. From pin and welds to full-on AR assembly, Dave Wilson at D. Wilson Manufacturing is a name that should be on your very short list should the need arise.

To learn more about Dave Wilson and D. Wilson Manufacturing, we recently sat down with the man himself for the following interview.

Q: Dave, first things first…for a man of your reputation, you’re a lot younger than I thought you’d be. How long have you been involved with firearms?

Dave Wilson, D. Wilson Manufacturing – I’ll start by saying I had a very interesting childhood. For some reason, my parents were somehow OK with me starting to buy guns when I was around seven or eight years old. I was always interested in guns.

Fast-forward 10 or 15 years, I was in college, and I was trying to figure out something to do. I decided that with my mechanical aptitude, I should probably go into engineering. That said, that whole time I was tinkering with guns, buying them, and selling them.

Then one day, I stumbled into an engineering machine shop on campus and I befriended the old codger who ran the shop. He taught me a lot about machining. I started getting a lot of ideas about projects I could make and things that I could do. I started getting really interested. By the time I graduated, I had hooked up with a local contract gun part manufacturer. I ended up working for him for a few years. Then, within the last few years, I decided to go out on my own and start working on guns all the time.

Q: Can you talk about your first experiences working with the AR platform prior?

Dave Wilson, D. Wilson Manufacturing – I was always very fascinated with machining, and for some reason, my parents were very against me going to Vo Tech in high school. They wanted me to take honors classes, and at the time, I didn’t really argue.

When I got to college, I also started taking entrepreneurship classes…I did that because I realized that I had all of these cool product design ideas. Of course, I did not lead on to anyone that they were gun-related. So, between those classes, I just found myself in the machine shop learning machining and working on stuff.

The original thing I was trying to build was a Colt XM 607, which was like the precursor to the CAR 15. It was like Colt’s first collapsible stock gun, and it basically looked like a shortened A1 stock with a funky latch mechanism on the buttstock…and these guts inside of it that made it collapsible.

I just was very compelled to build one of those. I reverse-engineered it from patents that I could find at the time, and someone else was kind enough to lend me a reproduction of one of the stocks. I managed to get enough information where I could recreate one.

I then realized that “Oh man, if I can recreate this, I can do all kinds of stuff.” Then I started making parts for an old Colt survival rifle, and then I was making safety selectors for a while…It was kind of crazy. I was doing all of this out of my college dorm room (laughs).

Q: What kind of machines were you working on back then?

Dave Wilson, D. Wilson Manufacturing – All manual machines. I started with the basics. But, by the end of my college tenure, I was starting to learn some CNC machining, but not a lot. Unfortunately, I did not have completely free rein. Being on a college student budget, the sky was also not the limit in terms of investing in projects.

Q: You didn’t dive straight in to what you are doing now at D. Wilson Manufacturing, is that correct?

Dave Wilson, D. Wilson Manufacturing – After college, I spent a few years bored and itching to create. I was this newly minted engineer working for a big defense contractor…I still really wanted to do stuff on my own, but I didn’t have the same access to a machine shop as before. So, after a year or two, a friend of a friend introduced me to this guy that did contract manufacturing, he made handguards and bolt carrier groups. It sounded kind of cool. At the height of it, we were probably making around 4,000 bolt carriers a month. It was pretty wild and eye-opening to me about how open and accessible the gun industry is.

Because of this opportunity, I started working on some of my own side projects again. Three or four years ago, I decided that I wanted to start offering services for myself. So, I bought a small lathe and mill and started doing stuff on my own. Other people became interested and started wanting stuff done for them, and then about two years ago, I bought some bigger equipment and realized that “you know, I really can do this.” I started a small e-commerce website so people could start to submit work orders for what they wanted to be done, and it’s been growing ever since.

Q: A lot of your early work was with Knight’s Armament, correct? I can recall D. Wilson Manufacturing’s involvement with production of a wrench that was somewhat sought after…

Dave Wilson, D. Wilson Manufacturing – Another project that I was working on in college…I wanted to build an upper using a (Knight’s Armament) URX rail, and at the time, it was tough for an individual to do it because you had to send the parts off to some Knight’s- certified armorer because Knight’s was very reluctant to sell the URX wrench to a civilian or anyone who was not a Knight’s dealer.

So, I got the rail, and I thought maybe I could make myself a wrench that would work. I did a write up on AR15.com, and I told folks that I was going to figure out how to do it. By this time in my college career, the guy had gotten so sick of me being at the machine shop every day that just gave me a job…So, I figured out how to reverse engineer the wrench, and I made a few rapid prototypes and figured out if it would fit.

I then made one, and it was really cool. I ended up reporting back on the thread that I had made one, and Reed Knight ended up chiming in. He thought it was pretty cool and mentioned to let him know if I needed any help. I was like, “Oh shit, this is crazy. (laughs)”

So, when I was first starting off, I only really did Knight’s Armament stuff…URX installs for people, or flush-fit URXs. I started making and selling the barrel nut wrenches, as I could make them way cheaper than what Knight’s was selling them for. I think at the time, if you could find one, they were like $400. I was like, “oh man, I can make these things for 20 bucks, sell them for 100 and make a killing.”

Dave Wilson, D. Wilson Manufacturing – So, I started doing that, and that’s how I made my niche with all of the Knight’s Armament guys…and I started doing more and more. For the longest time, I only did stuff with SR-15s and SR-25s, but over the last few years, I like to think I have branched out. People started asking if perhaps I could install X rail for them, and to me, it was not a problem to help them out, and that’s continued to this day.

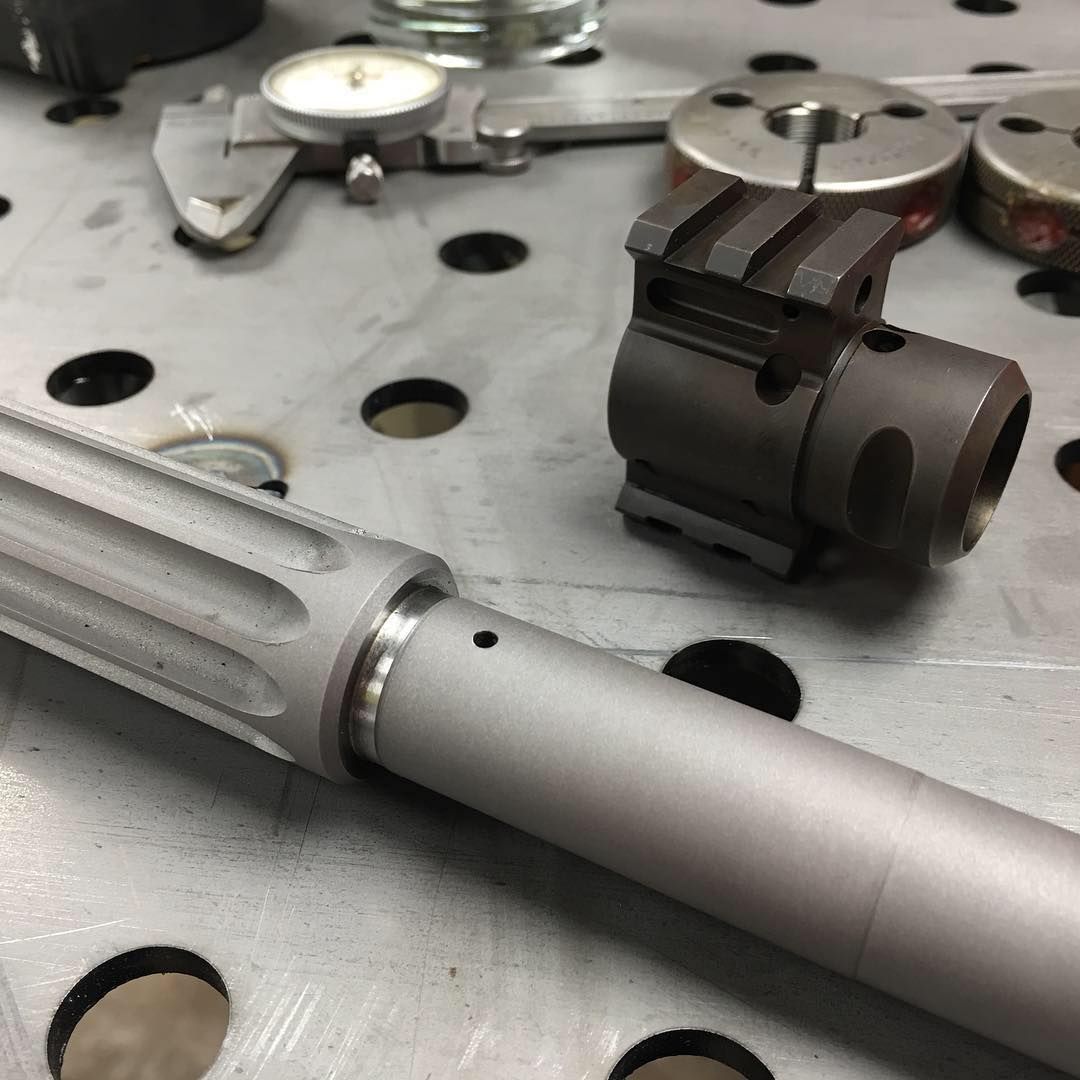

My latest thing at D. Wilson Manufacturing is doing Lewis Machine & Tool MRP barrel conversions, and that’s been an interesting project. The MRP is a monolithic rail platform, so the rail is one solid piece with the upper receiver, so instead of having a normal barrel nut like every other AR-15 out there, there are two cross bolts that hold in the barrel. The good thing about that is that you can change out the barrel relatively easily.

The downside to that is you can only use LMT’s barrels in the platform. So, one night after having a few beers, I decided I was going to figure out how to overcome that. What I ended up developing was a collar system that will allow you to take an off-the-shelf AR-15 barrel of any caliber, any length, any gas system configuration, and put it in an MRP chassis.

Q: D. Wilson Manufacturing is also quite well known for your pin and welds…I can’t say I’ve seen many do better than what you are putting out. Any secrets to what you do?

Dave Wilson, D. Wilson Manufacturing – Well, there are a few trade secrets, (laughs) but I think with the growing popularity of suppressors, and people understanding that there are creative ways to make your gun shorter and still comply with the 16” rule. So, it is growing in popularity. More and more companies are making short barrels and corresponding muzzle devices that will get you to 16.”

A lot of people who are traveling frequently or are traveling out of state and want a shorter gun will simply just pin and weld the muzzle device, so you still get to 16” and you don’t have an SBR, so you can pretty easily cross state lines. It certainly seems like it’s becoming more popular, but then again, that could just be because I do a lot of them.

Q: What other kinds of things do you enjoy working on at D. Wilson Manufacturing?

Dave Wilson, D. Wilson Manufacturing – I do get oddball projects from time to time that people ask me to work on, but I try to balance those jobs with ones where I simply get an upper, take it apart, chop the barrel, put it back together, and pin and weld the muzzle device.

Those are pretty standard jobs for me…versus a project like someone who recently sent me the parts to build a mini-M110 in 5.56. To me, that’s a cool project because it’s something that not everyone else is doing. I feel somewhat fortunate that I am getting to work on these kinds of oddball projects that not a lot of people have done before.

Q: How would you describe yourself in terms of a job title?

Dave Wilson, D. Wilson Manufacturing – I’d say a “firearms machinist.” It’s always interesting trying to find ways to describe what you do for people. I wouldn’t necessarily say that I am a traditional gunsmith. I don’t put butt pads on shotguns or do checkering work or anything like that. D. Wilson Manufacturing really just does machining and assembly…Mostly on AR-15s and AR-10s, but I do some Sig MCX stuff…I am trying to learn a little more about AKs, as a lot of people are asking me about AK stuff.

Q: With your unique perspective, what’s your overall opinion of the AR platform?

Dave Wilson, D. Wilson Manufacturing – The AR is just a really versatile platform. The end-user really has a lot of leniency and adaptability to adapt it to what they want to do…Any barrel length and caliber under the sun, chances are somebody makes it, or you can get an off-the-shelf one modified to do what you want. There are all kinds of different ways to configure it as far as stock, grips, and sighting mechanism.

So, in that regard, it’s no surprise how popular it’s become. The sky is the limit in terms of how you want to configure it to how you plan to use it.

With that said, I think there are some challenges from a machinist’s perspective. You have all of these different OEMs making parts for the AR platform, and while there is the Mil-Standard TDP for the design on the M-16 when it gets into the commercial market, everyone has their own twist on what their design and the tolerances should be.

So, you can get into some situations where maybe OEMs err on the side of a looser tolerance. As a result, perhaps things don’t fit together as they should. From my perspective, this can be frustrating. I will say that it is a lot more frustrating on the large frame guns than it is on the small frame ones.

Q: What’s your opinion on folks who choose to build their own ARs?

Dave Wilson, D. Wilson Manufacturing -I’m all for people trying stuff on their own and learning. If they are happy with their craftsmanship, I am more than happy that people are out there trying stuff themselves. Not everyone has a milling machine or a lathe in their basement or garage. So for things like shortening and threading a barrel, I’d be happy if people reached out to D. Wilson Manufacturing. More than that, though, we’re always happy to help people with things like basic assembly.

Some folks just don’t have confidence in their skills, or perhaps they don’t have the specialty wrenches or torque tools to do it…or some of the things like Loctite or Aeroshell grease.

As we discussed earlier, pin and welds are still probably the biggest thing that I fix for people at D. Wilson Manufacturing. Often times, I find myself fixing the work of other gunsmiths. The gunsmith may have not necessarily known what they were doing, and somehow pin and welded the device incorrectly.

Sometimes I find that they did not actually permanently attach the device to the barrel and/or if it is a suppressor mount, the suppressor may no longer engage the mount. I’ve seen all kinds of crazy stuff. I’ve seen where gunsmiths will drill the pinhole through the barrel…like into the bore (laughs). I’m like, what were these people thinking?

Q: Looking back at your journey so far, how does it feel to be able to do what you love as a full-time job?

I really find it fortunate that people come to me and ask me to do stuff for them and that when I am done, they are appreciative of what I do. If you asked me, even 3 years ago, that this would be to the point where I am doing it full time, I would have looked at you like you were crazy.

I love it, but It can be tough, and there are some long days in the shop. In the last year, I have brought on two people part-time in the shop to help get stuff shipped, turned around, and out the door…

Another guy I work with does some assembly work, but I still do most of the machining at D. Wilson Manufacturing myself, but it’s gotten to the point where I have to bring people into the shop to help get stuff turned around quickly. It’s an active concern of mine, as I like to turn stuff around quickly, but as my name grows more and more, it’s harder to do that as the workload increases. That said, I’m committed to being a reliable and dependable resource for anyone who needs me and the services that I am so happy to be able to offer.

###