From time to time, we like to reach out to different firearms manufacturers to hear first-hand what they’re all about, When it comes to building an AR, we find manufacturers always have some interesting perspectives, and depending on your needs and budget, may have products that interest you. As such, If you know of an interesting company you’d like to learn more about, please be sure to let us know.

Earlier this week, we were able to speak with Travis Hamlin of APOC Armory about his company and its line of cold hammer forged barrels for the AR platform.

Q: Thanks for taking the time to chat with us about your company. Can you tell us a bit about how it began?

Travis Hamlin, APOC Armory – I started the business as a hobby. I had long been fascinated with the AR-15. Everything about it appealed to me from a very young age. It was the looks, and the iconic nature of the firearm. I wanted more than anything to buy one, but before I ever bought a factory AR, I ended up attempting to build my own.

Q: Building an AR as your first isn’t an approach that everyone takes. What made you decide to go that route…and was it successful?

Travis Hamlin, APOC Armory –I think I have always been a hands-on type of person, and I like the idea of a challenge. I spent a lot of time and money and research and gathered together all of the parts I needed, and I was able to put together my first rifle.

I learned quite a bit during that build process, and frankly, putting it together was a lot of fun. I also found it very relaxing. Before I knew it, I was building another and another. It was very addicting and satisfying. It wasn’t long before I started to turn some of my friends on to what I was doing, and a few of them became enamored with the platform as well.

It was at that point that things really started to take off. I had always heard the phrase “do what you love and you’ll never work another day in your life” and it’s certainly true for me. To be able to do the build, source the parts, and see it function at the end is so rewarding.

Q: How did that lead to you taking the leap and starting a company selling AR parts?

Travis Hamlin, APOC Armory – It was around the time that I really started putting together rifles for friends of friends that I also started selling parts, but there was no company name. I ended up partnering with a friend and he helped me come up with a name. We racked our brains for something to call what we were doing. At the time, we had toyed with the idea of calling it Apocalypse Arms or something, but we ended up shortening it to just “APOC Armory.” (laughs). I think “Apocalypse Armory” was already taken.

After the business became official, one of the first things I did was work with Toolcraft to have our name machined into the side of the bolt carriers. We ended up selling a lot of those, as well as a few different types of AR 15 parts and that kick-started us. I felt like the bolt carriers were of good quality, and it inspired me to look for something that I could really focus on. I wanted to offer something that was high-quality, that maybe not everyone else was offering, and offer it at a very reasonable price. That product ended up being our Apoc Armory cold hammer forged barrels and uppers.

Q: I think cold-hammer forged is a term that is tossed around a lot. What does that term mean to you and why was it something you felt worth pursuing?

Travis Hamlin, APOC Armory – Once I had a few builds under my belt, I was looking for something that would help increase the overall longevity of the builds I had been doing. Very early on, I knew the importance as a builder of selecting a high-quality bolt. The BCG was one area I knew it was not wise to skimp on.

From there, I really started diving into the ideas behind the different types of barrels that were on the market. The thought that a certain type of barrel could last a bit longer in between replacement seemed like something appealing. I was not going to be facing down hordes of zombies or anything silly…but I did like the idea of a barrel that I could run hard, especially if I was going to a class and shooting 6 or 7 mags in a pretty short window of time. When I was going to the range, handing rifles off to friends who were sometimes new to the platform, with that…firing fast and long strings of fire was regular thing. Compared to a lot of guys out there, I was running my guns pretty hard (laughs).

“How much, how fast, how intense?”

I ended up using a few different cold-hammer forged barrels on builds and I became enamored, and I didn’t understand why more manufacturers out there didn’t offer them instead of barrels that were button cut. There’s absolutely nothing wrong with a good button cut barrel, mind you…and I want to make it clear that for most shooters, it’s not something that is absolutely critical, but for my workhorse guns, I just liked the idea of a cold-hammer forged barrel.

Again, I can’t say that it is something that everyone will benefit from, but I do think they offer some advantages. It comes down to how much you’re shooting, and how fast and intense you plan to shoot. I’d take all that into consideration as you look into whether a cold hammer forged barrel would be worthwhile for your build.

Q: For our readers who may be new to the idea of a cold-hammer forged barrel, can you explain the process in basic terms?

Travis Hamlin, APOC Armory – With button rifling, you’re basically taking a barrel blank and they drill the rifling into it….with cold hammer forging, they take what they call a mandrill and they take a blank and they hammer around it, compressing the steel, making the steel even harder than it was before. Then they turn the barrel. The process just makes it stronger. It can work to extend the life of the barrel You see it in a lot of pistol barrels, but the companies don’t make a big deal out of it.

There’s a lot more detail you can get into on the process, but the gist is it is something done that’s not quite as common here in the United States. That’s due to the machines to do it being a big investment. For a lot of companies, the juice…might not be worth the squeeze, especially when for a big majority of shooters, they may not use their rifles in a way that really justifies needing one.

Q: Can you talk about how you came to start selling your barrels?

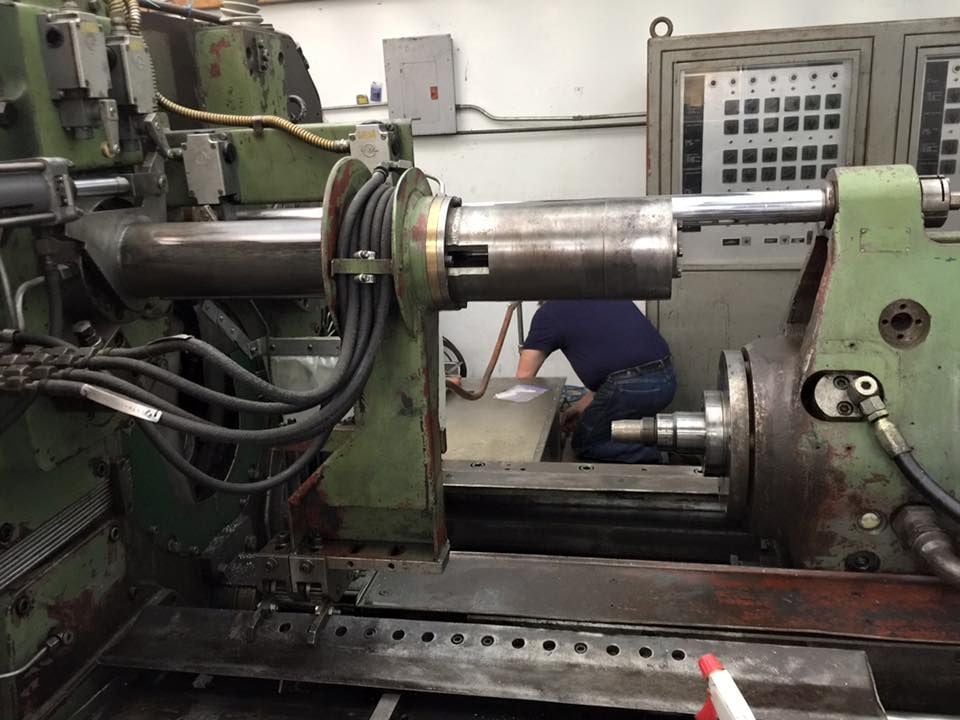

Travis Hamlin, APOC Armory – We were approached by a cold-hammer forged barrel manufacturer here in the United States that had brought back a machine that I believe was from Romania, built back in the 1960s.

It was missing some parts, and they were a machine shop so they actually rebuilt the parts, and rebuilt the machine so that they could start forging cold-hammer forged barrels. Not long after, we began selling our own line of cold-hammer forged barrels that they manufactured for us.

Currently we offer an APOC Armory 16” .223 Wylde 1/7 twist. It is 4140 steel that is QPQ nitride treated. That’s our most popular barrel and it’s the one that we now offer in our Titan line of uppers. We also offer a 20” 5.56…it has a 1/8 twist.

Q: What has the feedback been on your cold hammer forged barrels?

Travis Hamlin, APOC Armory – The issue with cold-hammer forged barrels is that there are only a few manufacturers that actually make them. It’s a harder process. So, full retail to get a good, quality one has been about $250. We sell them for slightly less than that, but I don’t think you’re getting any less quality, you’re just not paying for a name.

I work with a 3-gun team that all use the APOC Armory Titan upper, and they’ve put thousands and thousands of rounds through them. They’ve been using them for about four years now, shooting weekly for practice and whatnot…I know a few other guys that have well over 10,000 plus rounds through them. Personally, I’m still using the gun that has the original sample barrel they originally sent over in it. That gun is also well over the 10,000 round mark.

These are not extreme numbers for a cold hammer forged barrel, but I do think it at least hints at the idea that a cold hammer forged barrel may offer some advantages as far as longevity. Again, it just comes down to “does the shooting you do warrant it?” With the way you shoot, will you be able to realize the advantages that a cold hammer forged barrel can potentially offer? Maybe…maybe not. It’s certainly something I think an AR builder should at look into and see if it is right for them.

###

2 - 2Shares