Lubrication and the AR-15…talking to many experts, we understand clearly that a majority of common malfunctions we see with the platform can be remedied with proper AR-15 lubrication. That said, just what is a proper lube to be using?

It’s a topic I pay attention to, as I’ve used almost every lube on the market at one point or another. While I’ve only had a truly negative experience with one that turned to something akin to glue, I’m always eager to learn about new products, or those that earn repeated praise from those I respect.

One product I keep hearing about from folks in the industry is CherryBalmz. Roger Wang of Forward Controls Design, and Chad Albrecht of the School of the American Rifle, both have spoken highly of the company’s lubricants.

To learn more about his insights on AR-15 lubrication and CherryBalmz, I reached out to the company founder, Dallas Frohrib.

Editor’s Note 9-13-22…we have heard multiple reports of unfulfilled orders and we have been unable to contact the company for more information. Buyer beware…

Q: The first time I heard of your company was via a post from Forward Controls Design…CherryBalmz and FCD partnered to engineer their SGSO lubricant. Not long after, I heard you mentioned in posts about AR-15 Lubrication from School of the American RIfle…

Dallas Frohrib, CherryBalmz – Yes, it was a great project. The opportunity for my company to partner with Roger to engineer the SGSO was actually a lot of fun, and an honor, frankly. Roger from FCD and Chad from School of the American Rifle are both phenomenal guys to work with. They have absolutely zero tolerance for BS, and extremely high expectations of themselves and their work.

Chad loves slaying sacred cows, which is something I run into daily talking about AR-15 Lubrication, and Roger is singular in his focus on ensuring any part FCD puts out is not just of the highest quality, but that it’s also not just some gimmick or cosmetic thing. It has to add function not already out there.

The three of us all face similar battles in going against the currents of popular gun culture to put out the best products and information possible, regardless of what’s in vogue, or what people, often very accomplished people, think they know.

Q: Let’s start with a bit on who you are and how your company came about…

Dallas Frohrib, CherryBalmz – I actually had no idea that I’d ever wind up doing something like this, as my background isn’t in the hard sciences. It’s all international relations, communications, and politics for the most part. 100 percent of what I know about tribology, which is the science of friction, lubrication, and interacting surfaces, I have learned since starting this company.

The first couple of years was like drinking water out of a firehose, studying under some very talented people. I didn’t even know the word “tribology” myself until just before I got this company going, so it’s been a very interesting journey.

Q: How did your background lead you up to where you are today then?

Dallas Frohrib, CherryBalmz – I actually didn’t intend to start the company, as I’d spent almost my entire adult life at that point either working in D.C., or overseas out of D.C. This included working on Capitol Hill, covering various Homeland Security and International portfolios, and a cool opportunity to undergo the US Air Force’s Air Command and Staff College through a Capitol Hill program. None of it was related to tribology, or even guns that much, in a professional capacity.

That said, I’ve been intensely into shooting since I was a kid, including winning a national championship with muzzleloaders when I was sixteen, and later on in the Army National Guard I also competed in a type of run-and-gun combat-oriented M-60 competition, before college. And lots of flavors of competitive shooting in between, but it always took a backseat to school or work. But yeah, I’ve always been into competitive shooting, since I was a kid.

The Beginnings of CherryBalmz

Dallas Frohrib, CherryBalmz – As far as what got the ball rolling on starting CherryBalmz, it actually began after I had a gun lube fail on me. I’d been asked by some former colleagues to spend a few months overseas in the Republic of Georgia to help do some election observation and democratization work, which I’d done professionally for a few years as a Resident Country Director for the International Republican Institute, in Azerbaijan.

When I finally got back home, a cousin of mine had been wanting to learn how to shoot, and like many shooters, especially from military backgrounds, I always clean and lube my guns before I put them away after a range trip.

The thing was, it had been about six or seven months since I’d shot it and returned from Georgia. When we went to shoot, about every third or fourth round the slide wasn’t fully going into battery. Now, this is my workhorse…a Sig 229, and I knew the mags, ammo, and even the recoil spring were good, as I’d just replaced it about a thousand rounds earlier. It had never done this. I took it apart trying to figure out what was wrong, and I noticed that the lube that had been on while in storage felt a little bit tacky.

Now, this was supposed to be the most whizz-bang stuff out there, so when I got home I Googled the lube and added the word “tacky” and found out all sorts of bad reports about the lube, which was a Teflon-based grease.

A ton of bad info kept coming up, including other reports of it going tacky, but even more crazy was how bad Teflon was in DI ARs, because of the toxins it releases…It’s not something I’d ever recommend for AR-15 lubrication…

Q: I’ve heard that before. What kind of toxins?

Dallas Frohrib, CherryBalmz – We’re talking carcinogens and literally a pair of nerve agents on the chemical weapons list, that are all bio-accumulative…so they just keep adding up in your system. They’re fine in most guns, but the temps and gasses in a DI AR have them blowing back right into your face…Same with suppressed guns.

This was nuts to me, but when I dug around trying to find a gun lube that didn’t have any Teflon in it, I could only find a few, and all but one of them also had some pretty bad reports of going tacky. One though, had graphite had in it, I got some, and the gun ran flawless.

The Problem with Graphite

Boom, problem solved, right? Well, awhile later I realized the first lube I’d been using had been all the rage back in the day, and had hidden problems, so maybe I should google the graphite stuff too, just in case.

And that’s when I learned that graphite causes galvanic corrosion between dissimilar metals…As in, steel and aluminum, like my Sig, and ARs. Turns out Armalite even has a warning against it in their manual, and the Air Force banned it.

So between all that, it was blowing my mind…I simply could not find a lube that didn’t have Teflon in it, wouldn’t shut my gun down, damage my gun, or potentially harm me with toxins coming off it.

It was obvious something weird was going on in the gun lube world, and I ended up digging around deeper online, and that’s when I came across the concept of tribology.

I was so “sketched out” by the gun lube market that I decided to track down some sort of relevant tribologist that knew something about lightweight machines, so that I could just get a recommendation on some sort of pint of industrial lube that I could pick up for twenty bucks, or something.

And this is where I got lucky, frankly. Right guy…perfect timing…mutual curiosity, and frankly, a killer market opportunity. I introduced myself and started explaining what I was hoping for, with the problems I was seeing, and it blew his mind as a tribologist that gun owners were using oils in unsealed, sliding machines. It was an absolute absurdity to him. As in, “Dallas, that’s the stupidest thing I’ve ever heard, man.”

Q: Can you explain why using an oil for something like AR-15 lubrication was such an issue for him?

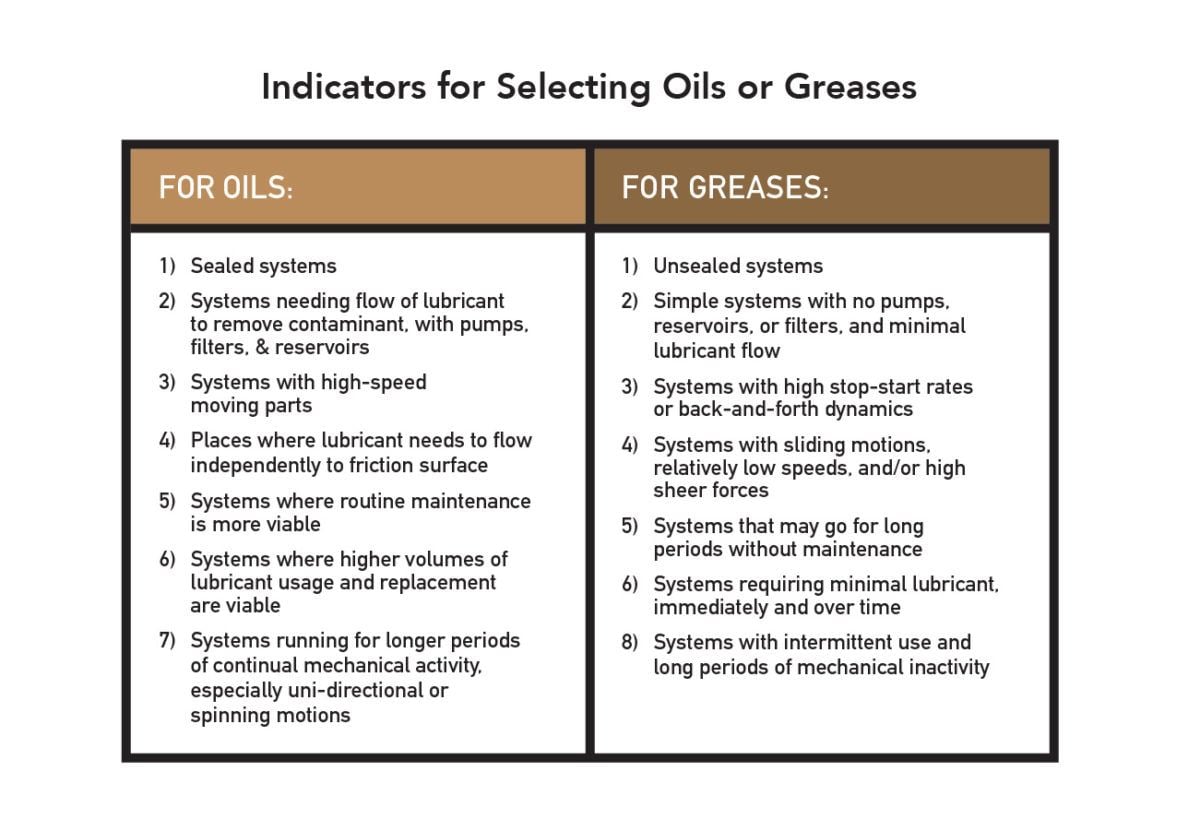

Dallas Frohrib, CherryBalmz – He explained that unsealed machines get greases, because oils are classed as flow lubricants, while greases are classed as sealing lubricants. Essentially, oils are designed to take friction contaminant, including heat, away from friction surfaces. But they do this behind gaskets, with pumps, filters, and reservoirs.

Greases are meant to stay put, including on vertical surfaces under the violence of action, and seal friction contaminants and oxidative elements away from friction surfaces. A key thing he set me straight on, is that grease isn’t this NLGI Number Two “sticky peanut butter” we all think of as grease, but that it ranges from as light as cooking oil to as thick as a block of clay. NLGI triple zero to number six, the heaviest.

He and I got together for beers the following Friday, I brought the “box o’ gun lubes” we all seem to accumulate, and he brought a friend of his who is probably one of the top “grease guys” on the planet. The thing is, neither of these guys are “gun guys,” so they were looking at this as a uniquely challenging type of machine, without any of the cultural bias or preconceived notions endemic to the gun world.

Long story short, we discussed possibilities, they geeked out on the challenge, and with their help, I got this company going. I also took one giant deep-dive into their world of tribology, just so I could understand what they were talking about, and so that I could translate it for the shooting community.

Q: So, what was this process like, working with them?

Dallas Frohrib, CherryBalmz – Utterly illuminating. With neither of my guys being shooters, they were looking at things like energy flows, friction issues, the dynamics of the moving parts, and just looking for universal patterns and principles, combined with my insights into their operational realities.

We weren’t coming up with a lube first, we were trying to understand the reliability factors guns experience first. And that’s a big, big difference of perspective. Only once we felt we had a command of these reliability factors did we actually start engineering a lubricant for them.

Q: Can you explain specific challenges unique to AR-15 lubrication, or firearms in general?

Dallas Frohrib, CherryBalmz – Absolutely. The biggest thing with AR-15 lubrication is that these are unsealed, sliding parts. In every industry on the planet, if a machine is unsealed and doesn’t have lubricant support systems, like pumps, filters, and gaskets…they get an appropriately weighted grease, because of grease’s sealant properties.

Again, oils on machines like guns was just an absurdity to these guys. The only time you see much of an exception to that, by design, is things like motorcycle chains, but even a bunch of them have oilers nowadays.

AR-15 Lubrication – “An Absolutely Filthy Energy Source…”

Second, these machines operate with an absolutely filthy energy source. Especially DI guns or when firing suppressed, they’re just tossing relative handfuls of super-heated friction contaminant right into all these unsealed friction surfaces.

And third, it turns out, guns are the only class of machine on the planet that get 100 percent of all the energy they need to cycle under in only the first 1 to 3 percent of part travel. After that, every single speck of friction in a gun is sucking energy out of the moving parts, slowing them down.

What we found out is friction is cumulative inside of guns, and every gun has its tipping point where if you add up enough of that friction, and suck enough energy out of those moving parts, they slow enough and it will have a malfunction.

On one hand, this may sound a bit obvious in hindsight. But even after the intense study we’d done, we had no idea just how incredibly profound an issue friction was across so many malfunctions, until we started applying our first lab batch of lube to finicky guns.

Q: What would constitute a “finicky gun” to test on?

Dallas Frohrib, CherryBalmz – I’d asked friends and family to come up with the most finicky guns they could for us to test. And what we found was that as long as the mags were good, the springs were good, and the ammo was good, literally over 98 percent of all malfunctions were friction related, in one way or another, but it just wasn’t obvious until all these problems instantly disappeared with our lube.

Failures to eject, failures to feed…these are symptoms, not the actual problem. But the totality of this didn’t smack us in the face until we put our lube on these guns. As long as mags, ammo, and springs are good, they go from finicky to completely reliable, instantly. That final two-ish percent when they don’t is when a part is broken or out of spec.

“It’s really hard to believe until you actually see it yourself…”

It’s turned out to be a surprisingly effective and cheap diagnostic tool that way, on whether or not a gun needs a smith. It’s really hard to believe until you actually see it yourself, and that’s actually been one of the biggest challenges we’ve had with our products. It’s completely outside of people’s frame of reference or experience, so they just don’t believe it until they see it.

Q: Back to the AR platform and AR-15 Lubrication…what stands out about ARs specifically?

Dallas Frohrib, CherryBalmz – So, in regards to AR-15 lubrication, you hear a lot of people say ARs like to run wet, right? They’re more lube sensitive than most because the DI system is pumping a lot of gas into that action area where the lube is.

The thing is, when we started running the numbers, DI guns were simply burning off oils a lot faster than they should have been. CLP, motor oil, whatever…We knew we were missing something, as the heat and volume of the gas just couldn’t account for the amount of burn-off that was occurring.

When we dug into it, the fouling that all of us have been calling “carbon” for so long? Well, it turns out there’s almost zero carbon in combustion fouling at all. It’s about 98 percent lead and copper particulate, coming out in rough sphericule shapes between .5 micron and 10 micron, with the final two percent being things like tin, antimony, or steel, depending on the composition of the cartridge.

In rifles you’re looking at a 70/30 copper-to-lead ratio, and in pistols it’s flipped, at 30 percent copper, 70 percent lead. Forensic scientists can tell if a pistol or rifle has been fired from this combustion composition.

Also, about 20 percent of the lead on most ranges is coming from the priming compound, which should tell you a lot about the ridiculousness of a lube being advertised as “green” – it’s always contaminated after the first shot. But yeah, almost all the carbon in the powder is converted to gasses, like CO2.

AR-15 Lubrication – Burn-off in Direct Impingement ARs

So it’s this super-heated, dense metal particulate that was causing so much of the AR-15 lubrication burn-off in DI ARs, and suppressed guns. The temperatures inside a cartridge at ignition are right around 5,000 degrees Fahrenheit for a microsecond, and go down to about 3,000 degrees Fahrenheit two to six inches from the chamber.

You can see evidence of this in red-hot barrels fired to destruction, as steel starts turning red at around 1,050 degrees Fahrenheit , bright red at about 1,500 degrees Fahrenheit and has its forging and malleability temps starting around 2,000 degrees Fahrenheit, depending on the steel.

And you can be certain those brief pulses of gas are far hotter than the steel, if it’s getting that much metal up to those sustained temps. You can also see evidence of these temps in copper brazed to your bolt tail, as copper’s melting point is 1,985 degrees Fahrenheit .

The gas temps drop rapidly as pressure and volume decrease, so you’re right around 2,300 degrees Fahrenheit at the gas port of a carbine-length gas system and at 17,000 psi, while in a rifle length system you’re looking at about 2,000 degrees Fahrenheit at the port and 10,000psi.

AR-15 Lubrication – The Most Under-Appreciated Friction Surfaces in an AR is…

The gasses are roughly 1,800-2,200 degrees Fahrenheit at the gas key before the BCG starts pulling back, but by the time the internal piston is open, which is only something like one cubic inch or so of more space, the gas temps right there are down to 700-1,000 degrees Fahrenheit Yet gasses an inch from the ejection port are rarely above 200 degrees Fahrenheit, which says a lot about the relationship between pressure, volume, and the temperatures of gasses.

These temperatures atomize these different metals, and under these extreme pressures in the bore they start getting recombined into this sphericule particulate, but it’s the density of these metals that allows them to retain such extreme heat for far longer than the gasses they’re carried in. And that’s the key friction challenge you find in DI ARs, and suppressed guns.

The friction of the particulate itself, and how rapidly it polymerizes or burns off most lubes. It’s also why the cam pin and cam channel are the most under-appreciated friction surfaces in an AR.

Q: So, what is it exactly that your lubes do that others don’t?

Dallas Frohrib, CherryBalmz – In short, one application of our lube gives you about ten times the shooting on one application over any oil. You’re looking at around 3000-5000 rounds on a typical carbine-length AR, and the lube is going to stay slick, reliable, and where you put it , for over three years on that gun.

What they do is give a tremendous edge in reliability over flow lubricants. They’re lightweight greases, the heaviest of which is about the consistency of a creamy mayonnaise.

They don’t get clogged up – that’s a misunderstanding that comes from only having experienced NLGI #2 greases, which actually are far too heavy for maximum reliability in guns. Our greases stay slick, and keep particulate trapped away from the friction surfaces, safely out of the way.

“How well will it lube, for how long, and under what conditions?”

Most of your readers are very tuned-in to quality, legit gun info, so they’ll know that most ARs can keep shooting for tens of thousands of rounds without cleaning, as long as you keep adding oil every few hundred rounds. And that’s cool. The question on any given lube you might select for AR-15 Lubrication isn’t, “Will it lube?”, but “How well will it lube, for how long, and under what conditions?”

If a guy wants to serve as his gun’s oiling pump, that’s fine, as long as he keeps adding it every couple hundred rounds. As long as he knows his lube’s limitations, and acts accordingly, he’ll be fine.

For us though, we set out to engineer AR-15 Lubrication that would provide absolute maximum first-shot reliability, and maximum total round-count reliability, on one application, and for that lube to last as long as possible on the gun in the open air. What we’ve engineered gives a tremendous edge to EDC that isn’t getting relubed regularly, or the nightstand gun that may sit for years without maintenance, or law enforcement duty guns, especially motor officers experiencing a ton of wind. For total round-count, we’ve even had belt-fed weapons go over 10,000 rounds on one heavy application, including an M2 in windy, sandy conditions in Texas.

The thing for me though, is after all of this time in tribology, I had a realization awhile back that, if we’re trusting our lives to these machines, isn’t it kind of absurd that any of us would just accept a couple hundred cycles or rotations before the machine quit working right, and needed lubing or other maintenance?

That’s like, a 19th century expectation of a machine. And none of us would tolerate that with any other machine in any other part of our lives. I almost feel bad that we only get 4,000 or 5,000 rounds in an AR on one application of our lube. Yet like everyone else, I was completely fine cleaning after a few hundred rounds, until I was exposed to better information…and results.

Q: Can you talk about a few of other lubes you offer that AR users might be interested in? I see that you have more than just the Black Rifle Balm.

Dallas Frohrib, CherryBalmz – Absolutely, we have five on the market right now, all lightweight greases, and each is engineered and optimized for a specific challenge in guns.

The Black Rifle Balm is about the consistency of creamy mayonnaise, and is roughly a #0 on the NLGI scale. The lightest, our Winter Balm, is about the consistency of a very light, very slick whipped cream, and is a 000. The Winter Balm, and our Rimfire Remedy, are both a trip to feel between your fingers for the first time. When you squeeze out a blob it looks thick, and doesn’t move, but when you touch them they are super light and offer almost no resistance.

The Rimfire is a 00, by the way, so it’s a bit heavier than the Winter, but both were engineered to stay put and act like sealants in their different challenges, while offering as little resistance to the moving parts as possible. The Rimfire Remedy has had finicky AR .22s go from multiple malfunctions per mag, to several thousand rounds of Golden Bullets or Wildcats without cleaning or re-lubing. It’s incredibly slick.

For AR-15 lubrication, The Black Rifle Balm is our workhorse grease though – it’s what you want for centerfires. The fourth grease is our Field Balm. It’s a little bit lighter but it’s engineered with a little bit more flow, so that it can be easily applied to assembled guns. All the others, you want to disassemble and apply. The Field Balm will flow just a little bit to get to places while you cycle the action, but will largely stay put, and gives you about 80 percent of the performance of the Black Rifle Balm.

Q: Anything else exciting coming up in the future?

Dallas Frohrib, CherryBalmz – As far as products go, we’re finalizing a lubricant for the actions of suppressed weapons, and have a couple specialty lubes we’re partnering up with Chad Albrecht at School of the American Rifle on to develop.

The Black Rifle Balm is excellent on suppressed guns, but it’s not optimized for them, which matters. In certain extremes it may just not get the job done right, even if we’ve had dozens of guys run their suppressed SBRs with it for several thousand rounds each on one application. Again, you have to know a given lube’s limitations.

We’ve put a lot into threading the needle with the Suppressor Salve, to withstand the extreme heat and gas pressures coming into an action with suppressed fire better than the Black Rifle Balm, but the challenge is pushing its low-temp reliability as far down as possible.

The trade-off with lube components is that high heat tolerance generally results in poor flow and usability at low temps – and vice versa, which is why CLP’s flash point is only 201 degrees Farenheit, which is less than half that of most motor oils.

We’ve spent more R&D time and resources on the Suppressor Salve than any other lube, so that should give an idea of just how challenging genuinely optimizing lube performance is for suppressed guns.

Another exciting project is the pair of lubes we’re partnering with Chad and SOTAR on. My company has been focused on maximizing reliability of the moving parts, but Chad has additional perspective, on a lot of gun reliability things, and shared two key needs we weren’t aware of.

One is an assembly grease designed specifically for guns. Right now people are using anti-seize, Aeroshell 33ms, or Aeroshell 64, each of which has drawbacks.

Q: Can you talk about the issues you have with them?

Dallas Frohrib, CherryBalmz – Anti-seizes often have silica particulate in them, which can cause fretting wear in vibratory or micro-movement environments, which is why the Air Force banned graphite. They also usually have such a heavy load of aluminum or copper that the threads of the barrel nuts can get loaded up before being fully torqued down to sufficient levels, which has been a concern of Chad’s that he’s had to develop work-arounds for.

With the Aeroshells, they’re generally better for assembly, but they can be hard to come by, so people are either relegated to getting hundreds of guns’ worth in a big grease-gun tube meant for lubing jumbo jet parts, or buying relatively expensive jars online of smaller amounts that someone has repackaged. In either case, while it works well, it’s not engineered for barrel assembly or gun use. Our solution should be significantly cheaper, more effective, and heck of a lot easier for AR builders to source.

The second we’re working on with Chad is a lube for the quick-detach mounts for suppressors, to prevent the fouling-lock that seizes so many of them up. We have solutions for that we’re testing soon, that should minimize or eliminate the problem entirely. We’re testing these in the next week or two, and are definitely looking forward to getting that out soon as well.

Q: Anything else you’d like to mention in regards to your company and/or AR-15 Lubrication?

Dallas Frohrib, CherryBalmz – As far as the company goes, I’m in the final stages of launching a broader tribology firm, focusing on advanced R&D of high-performance lubricants for lightweight mechanisms and machines.

We’ve literally moved the boundary of scientific knowledge downrange on ultralight, high-performance greases, especially with our Winter Balm, and there are a number of industries we’ve already developed formulations for…looking mostly at doing private-label R&D and manufacture, behind the scenes for existing brands, and some tribology consulting on hardware design as well.

Early this next year we’re also re-branding and relaunching our gun lubricants under an entirely new company and brand, which I’m excited to get underway.

###

1 - 1Share

I ordered Black Rifle Balm to try on a new AR build, the BCG felt noticeably “slicker” after I cycled it a few times with the charging handle. Several hundred rounds later I pulled apart the BCG to check for unusual wear and the lube seemed to stay where it was applied. The bolt and cam pin were still well lubed and moved freely. I like what I’m seeing so far…

I ordered over a month ago and after several emails have not heard a single thing back. I’m not sure if this company is even in business anymore. Apparently Dallas Was in international affairs and communications. But can’t for the life of him respond to numerous emails (Is he using Morse code?) Honestly, the product may be the best thing to happen to the firearms industry since 1776 but my experience with CherryBalmz has left me bitter and feeling robbed.

Dallas, I recommend reading.

Starting a Business All-In-One For Dummies https://a.co/d/8LTz4LD

E-Mail For Dummies

https://a.co/d/f5Jh3gW

We are going to edit this article to mention these difficulties as this is the 3rd time we’ve heard them.

Edited…

In the time I have placed my order I have spoke to one person that waited like 3 months and another that has waited 7 weeks. I understand that there was/is a supply chain issue. I took that into consideration, but when several people all have the same issue of the owner of a company pushing out excuses after excuses or not reading and replying to emails it becomes an issue. I have used the product in the past and it IS good, but I would seriously caution people to purchase through a distributor that has it in stock in… Read more »

They took my money months ago and regrettably the money from my friends and family that I sent this article to.

Dude is shitty, I’m honestly thinking about filing charges with other customers for theft. We are not ATMs, we expect a product in a timely fashion. There was no mention of a delay, no mention of anything. And the worst thing is he does this to people constantly, he is always making up excuses and extending the deadline. It was supposed to be shipped in 3 weeks, almost 6 weeks ago.

are you getting responses from him? We’ve reached out for clarification without success, and have placed a header on this page until we hear back.

Not one single response.

I placed my order on July 10th and have not heard a word from this crook. Please do the shooting world a favor and remove the content of this article and leave the warning you posted.

it’s a bummer because that crook has a lot of good information to offer. I have since purchased Wilson Combat grease and it’s amazing, I highly recommend folks give it a try. If my order ever comes in I’ll stick with Wilson Combat regardless.

Hello, I placed an order and sent a follow up email over a week ago and never heard back from them. My credit card was charged, is this a real company?

This is not a real company, they took my money and PayPal won’t even give me my money back, same with everyone I recommend their products to. Please remove this article so more people don’t get ripped off like my friends and me.

They WERE a real company, I don’t know what they are doing now. The fucked up thing is they are still taking orders. Literally stealing from people, I heard about them through Cola Warrior and figured I would give it a try. I have sent dozens of emails, Facebook, Instagram and still nothing. I’m sure if we all get together we can file charges against the business for theft. Theft is theft, if you take money from customers no updates, refunds or goods then you are guilty. Dallas Frohrib, if you are reading this you are a thief. Either send… Read more »

The best lube for an AR is 1/2 5w-30 motor oil and 1/2 high temperature lithium bearing grease mixed together. It’s as lubricious as oil without burning off and works in extreme cold.

Well they may have a good product but I can’t prove it.

I ordered one each of their product’s on 8/9/22 and they charged my card.

I have sent 2 e mails asking for a projected ship date.and I guess they are to busy charging card’s ro reply to my question.

I ordered going from your write up and am very displeased at the moment.

Greg

Join the club. He has ripped off hundreds. According to the ARFCOM threads he eventually ships but it’s like 6 months later. And it’s always excuse after excuse. Lots of people have gotten ripped off on that too. Like order 6 bottles and he only throws in 5 but says here’s extras. He has no clue how to run a business. Technically he has violated quite a few e-commerce laws. The 30 day law, consumer protection laws, FTC laws, and I’m pretty sure it’s over small claims court amounts so state and federal laws too for defrauding customers, taking orders… Read more »

If you haven’t seen it yet Cherry Balmz site has some good information on lubrication of a 1911 handgun just DO NOT PURCHASE ANYTHING FROM THEM. They will take your money and you will never hear from them or get your order. The following link is for INFORMATION ONLY.

https://www.cherrybalmz.com/post/secrets-of-1911-reliability-how-to-lube-for-maximum-performance