It’s not hyperbole to say that the ever-growing number of companies dedicated to modifying the Glock pistol are using elements and methods developed by Ben Simonson of Boresight Solutions. Ben is a true pioneer, developing many of his unique and highly functional mods from scratch, at a time when there was simply nothing to copy.

As fans of reliable firearms and thoughtful firearms modification, it’s hard to ignore what Boresight Solutions is up to, regardless of our usual focus on the AR platform.

To learn more about Boresight Solutions and their unique approach to the Glock (and other handguns), we recently sat down with Ben Simonson to learn more about the company and its passionate, “performance driven” approach.

Q: Ben, can you start with a bit of background on how the company started?

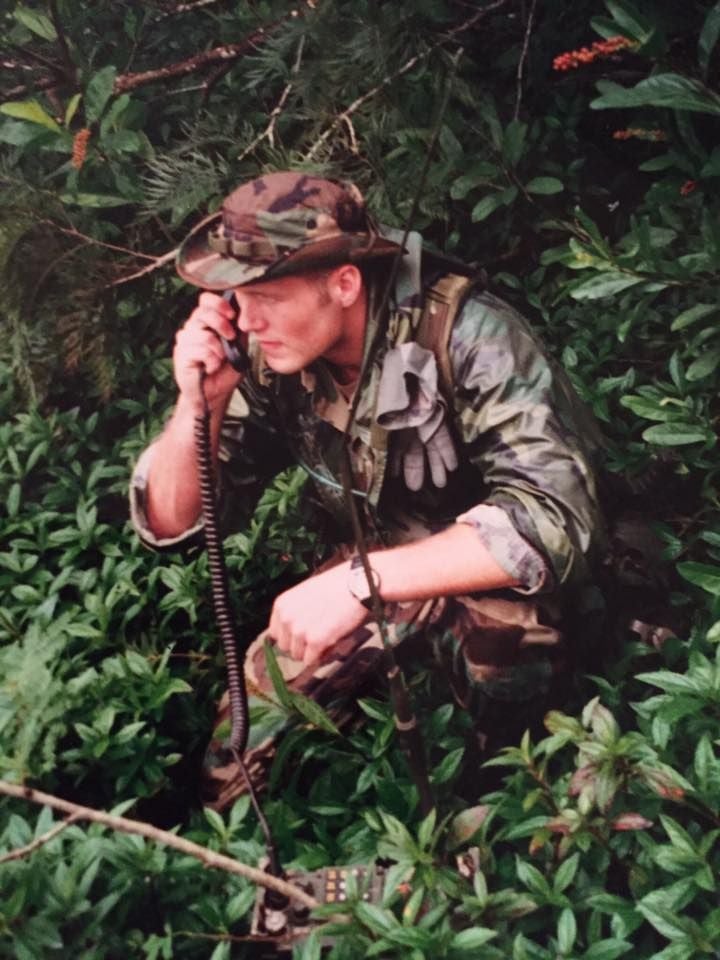

Ben Simonson, Boresight Solutions – I guess I should start by saying that I didn’t intend to actually start a company. It began when I got out of the military, and I wanted to keep up with my training.

As background, I’ve been around guns my entire life. My dad was a gunsmith, so I grew up literally with a gun in my hand. I grew up in Montana, and shot competition, and was always shooting. Basically, I love guns. I understand them, they understand me, and we get along fine (laughs).

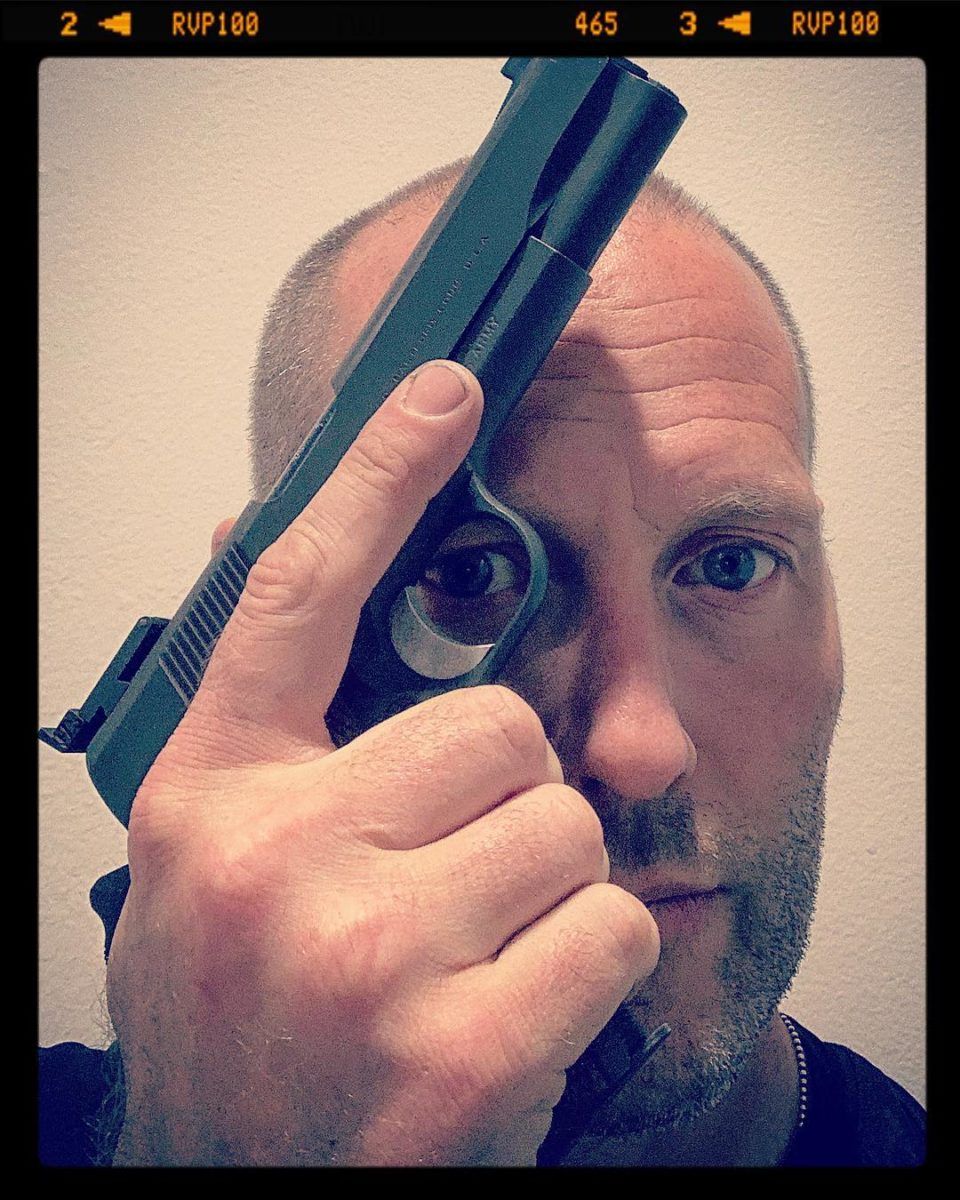

When I got out of the military where I was issued a Beretta, I decided I wanted to continue my tactical training, but I was sort of an esoteric guy shooting 1911s, Browning Hi-Powers and things like that. However, I was at these classes and I noticed everyone around me was shooting Glocks. My buddy the late Pat Rodgers used to say that “in police work, they call that a clue.” (laughs).

I figured I would get a Glock and try it so that I could dismiss it based on personal experience. Then I would be able to say that “I tried it, didn’t like it, and got rid of it.”

Well, I actually liked it. I found a lot of things to like about the Glock, and the things that I didn’t like about it, I was able to identify immediately because I was a shooter. I was able to quickly hone in on what I did not like, and think about how it could be improved.

“The gun was already ugly…”

There were only a few companies, maybe five, in the whole world that were carving up plastic guns around this time. This was in the early 2000s. I looked them up and I saw their work. I didn’t like how it looked.

I’m sure that it was functional, but I just didn’t care for the esthetics. Looking at what the professionals were doing, I decided that I was not going to spend money. My thought was that the gun was already ugly…I didn’t want to pay money to make it look worse.

Q: Were you hesitant that you might destroy the gun in the process, or did you go in confident?

Ben Simonson, Boresight Solutions – Frankly, I didn’t have any emotional attachment to it. I thought that I could figure it out, and because Glocks are cheap, if I ruined it, I would not be out a huge amount.

Prior to that, I was also always used to working with my hands, carving, sculpting, building things out of clay or whatever since I was a kid. So, it was kind of familiar for me. I just approached carving the plastic the same way I would whittle on a block of wood or something like that.

Q: Did you just go right in or did you you have an idea of what you wanted to do?

Ben Simonson, Boresight Solutions – I went in with a plan that I was trying to accomplish, and the end result was that it fit my hand quite nicely. But then I decided it needed some traction.

Now, I didn’t want to burn the traction into the grip in some sort of random pattern…I wanted traction on the frame where my skin contacted so I could get as much “meat-to-traction” on that frame as possible. I also wanted to lay it out in a pattern that looked like it made sense on the frame. Today, I call it “organic esthetics” where something looks like it was born that way and belongs that way.

Q: Did you know right away that you were on to something, or was the start of the business more organic?

Ben Simonson, Boresight Solutions – The very first gun I did, I did it for myself. I had no intention of going into business. That said, what I did ended up coming out pretty nice. The texture was laid on in a functional way. It looked nice and it complimented the lines and the shape of the Glock.

I ran that first gun in a class, and it accomplished everything that I wanted to accomplish. However, it did attract some attention, and someone at that class saw it and quickly talked me out of it on the spot.

As such, I went and bought another one, modified it and as it turned out, that one came out even better. At the time, I was shooting and training a lot. As a natural result of that, I found that more and more people were seeing my work, and they liked it. I started getting a lot of questions on if I could do it for them as well. That just grew and grew to the point to where I kind of had to go into business, if that makes sense.

Q: Were there other modifications you did on those early guns?

Ben Simonson, Boresight Solutions – I changed the sights, because I feel the Glock factory sights are just kind of placeholders. Also, I did some judicious honing and polishing of the trigger mechanism to clean it up. I threw a minus connector in.

Then, I also experimented with some extended controls like big, funky mag releases, slide stops and things like that, but I didn’t really care for them because they ended up being in my way. As such, I went back to something that was simpler.

Q: I think its similar with ARs, there’s a tendency to overdo it with things that don’t matter versus focusing on critical areas that deserve attention…

Ben Simonson, Boresight Solutions – That’s correct. On that first gun, the biggest improvement I knew I needed to be make was the grip, the ergonomics, because that’s your physical, mechanical “handshake” with the gun. If that handshake is awkward, then you’re at a disadvantage because it just doesn’t fit right…

When you grab your pistol, it should be a familiar, ergonomic handshake that you don’t think about, because it’s not distracting. You can think less about the process of shooting the gun, and instead just go to your fundamentals and “do work.”

“The more distracted you are…”

If you’re thinking about the gun and thinking to yourself that “oh, these finger grooves don’t feel right” and “the bottom of the trigger guard is beating up the knuckle of my middle finger,” or “ it’s slipping around in my hand,” or “this trigger has a really rough break”…all of that can be distracting. The more distracted you are by issues with the gun, the less efficient you are.

Q: Since you began in 2002, the demand for what you do has really taken off. Can you talk about the Glock modification market and where you think Boresight Solutions fits in today?

Ben Simonson, Boresight Solutions – There is certainly a lot of variety out there. Some companies focus purely on esthetics…those are the ones with elaborately cut slides with lightening cuts, elaborate patterns painted onto the frame, stuff that’s done to the frame like carving into it…artistically, it’s cool, but for functionality, it’s pointless.

Sometimes it can also compromise the functionality of the gun. I think the kind of person that buys a gun like that is usually not the kind of guy that’s putting tens of thousands of rounds through their pistols a year at training classes. They just want something that looks cool. There’s nothing wrong with that, by the way.

Q: I think it’s similar to the AR market…People are on different budgets and/or have different tastes, and that’s fine. The issue becomes when people market flashy or fun stuff as being “duty grade” etc.

Ben Simonson, Boresight Solutions – Where I take exception to it is when the people who are doing work like that market their stuff as a “fighting gun, a duty gun, a carry gun.” It’s just not. Rather, it’s a showpiece designed to showcase a person’s artistic ability. I know from experience that the things that are being done to guns in those cases are not ideal for hard use.

“narrow, niche market…”

As far as where we fit in today, Boresight Solutions has a nationwide customer base, and about half of that customer base nationwide is law enforcement. There are a lot of cops out there using our guns. There are also a lot of concealed carry guys using our guns, as well as professional instructors and people who shoot and train a lot. I see it as that’s our narrow, niche market…at Boresight Solutions, we don’t have to go after the mainstream consumer.

I say that because I think the mainstream consumer is perhaps looking for something more shiny or flashy. Because of that, our work may not appeal to them because, admittedly it can be somewhat boring to look at. However, the reason for that is everything that we do has a functional reason that has reliability in mind.

Q: Everything really has to take a backseat to reliability, correct?

Ben Simonson, Boresight Solutions – Right. If you’re building something that is designed to be a duty gun, you simply cannot do things that are going to compromise reliability. For example, ultra light springs, triggers that are not drop-safe, or match barrels that are too tightly fitted. Yes, they are super accurate, but if you get them dirty, they are going to bind and choke. I’ve seen it happen.

You can’t mill the slide to Swiss cheese, weakening the structure of the slide and the frame. You also don’t want to put on controls that stick out too far. That can be a snag hazard, so when you put the gun in your holster and lean on it, it’s likely going to drop your mag.

Avoiding the Bandwagon…

There’s a lot of aftermarket accessories out there that I call “me too” things because someone is just wanting to make something to sell and have their name on it. Not a whole lot of thought goes into it.

On the flip side of that, there’s some really intelligently designed, well-made stuff out there that does add to the performance of the gun. Sometimes, it’s in very little, subtle ways…sometimes expensive, sometimes inexpensive.

Modified vs. Custom…

Just grinding and stippling a frame and milling a slide and doing the exact same thing over and over for every client…that’s not “custom.” It’s “modified,” but it’s not custom. To me, “custom” means it’s tailored to the client. While Boresight Solutions offers a variety of packages, options and reductions to fit the grip to the individual, nothing we do is cookie-cutter. We can size it up, size it down, cut it up, put it back together in order to really optimize that handshake with the end user.

Q: Can you explain why that is so important?

Ben Simonson, Boresight Solutions – First of all, the ideal carry gun should fit the hand of the user. If you have a 5’ female with tiny hands, putting a Glock 21 in her hands is a recipe for disaster usually. It’s huge, it’s going to be hard for her to wrap her hands around it…it’s going to be harder for her to control, and she’s probably going to be less effective.

I have a lot of friends in law enforcement, and they have told me over and over again that they have seen performance increases simply by giving the person a smaller gun, or a bigger gun that fits their hand, if they have bigger hands.

Q: So, not only is it about the size of the pistol, but how it fits in the hand?

Ben Simonson, Boresight Solutions –That’s right. The gun should not just be some random thing out-of-the-box where it’s like “here’s your carry gun…go to work.”

It should be something that is better suited for the individual. This is where we can come in. While Boresight Solutions offers slide packages…they’re fairly boring and straightforward, rugged and utilitarian. Rather, it is plastic surgery that is our forte, because that’s the mechanical interface between the shooter and the gun…that handshake.

Fitting the grip to the individual, to me, that’s a lot of bang for the buck. It makes a big difference. That’s based on the feedback that we get from clients when they get it back…it’s easier to shoot when it fits your hand, and a lot of the mechanical interference is eliminated.

Q: Can you give us some examples of the basic “plastic surgery” you do to these guns?

Ben Simonson, Boresight Solutions – It would take too long to talk about all the things we do, but in summary, I’d say that a duty carry gun should be suited to the individual size-wise and handshake-wise…

Like, getting rid of the finger grooves so you don’t have them blocking YOUR proper grip. Undercutting the trigger guard so that it does not beat up the knuckle of your middle finger, or doing a glove bevel.

Q: What’s a glove bevel?

Ben Simonson, Boresight Solutions – That’s a modification I developed a long time ago…it’s gone mainstream and pretty much every shop now offers it, but it’s something that I developed almost 20 years ago. What it does is it opens up the inside of the trigger guard. It relieves plastic. It eliminates mechanical interference of the frame on your trigger finger so that when you’re stroking the trigger, you’re rubbing less of the frame as you press the trigger.

Q: From a high level perspective, can you do a quick overview of what are the best places to focus on if you’re looking to upgrade your Glock, or any handgun for that matter?

Ben Simonson, Boresight Solutions – For me, the areas where you want to spend money on the gun are the three places where you have the most physical contact with the gun, which is the grip, trigger and the aiming system.

Yes, you manipulate the slide, but you’re not physically in contact with the slide all the time like you are with the frame, the trigger and the sights. With the sights or the red dot, yes, you’re not touching them, but your eyes are in contact with them and using them.

I’m a big fan of trigger jobs because Glocks and a lot of striker-fired guns have a trigger where you pull the trigger back and the weight increases, and then you come to a wall. It’s almost like a two-stage trigger in an AR…breaking through that wall, on Glocks especially, it’s pretty abrupt.

Q: How does that impact a shooter?

Ben Simonson, Boresight Solutions – Well, when the break is abrupt, that “shimmies” the sight picture. You have your sights lined up on target, you’re pressing that trigger back, you come to that wall, and when you break through that wall, if it is abrupt, it disrupts your sight picture at that last moment of control. It spreads your group.

So, doing a trigger job on a Glock makes that break gentler, smoother, and less disruptive to the sight picture. For me, I’m a big fan of using the Apex Tactical Flat Trigger, combined with a Ghost EVO fitted 3.5 lb. connector…that’s my preference and also my number one seller at the shop.

Q: Can you describe what the Boresight Solutions customer experience is like should someone want to work with you?

Ben Simonson, Boresight Solutions – Most of Boresight Solutions customers are not local. We have a website with builders and packages so that a customer could go there and buy a gun.

Because we’re a stocking dealer, they can buy a new gun from our inventory, and go through the drop-down builder’s menus and spec out and order a full maxed-out gun with everything from matched barrel, to RMR, to trigger job. They can then and have it shipped to their FFL when it’s done. That said, most people still call us.

Compared to other shops, we offer a pretty confusing array of services, and even though we have a website where people can go and order something without ever speaking to us, pretty much everyone still calls. I encourage that. It’s like I said, “custom is not just modified.” This is a custom gun, tailored to you, to your hands, to your needs, to your shooting style, to your lifestyle.

“It’s more of an interview…”

Most clients will call, and I will spend on average about 45 minutes on the phone with them. It’s more of an interview than a sale. We bounce ideas back and forth. I ask them a bunch of questions. I ask them about their height, their hand size, their build, how they carry, what they carry, their experiences with other guns, their experience as a shooter, where they live, and how they dress.

As I am interviewing them and taking notes, In my mind I am narrowing it down to a set of features that I feel that I can recommend to them. While we’re talking, I’ll then have them get on the Boresight Solutions website with me, or I’ll get on my Instagram page and direct them to a relevant photo.

Q: You use the phrase “experience-based, performance driven”…can you explain what you mean by that.

Ben Simonson, Boresight Solutions – First of all, in terms of experience, I’ve been doing this longer than pretty much anyone else out there. When I got started there were only a handful. Of that handful, there’s now hardly any left.

For a while, Robar was the last one that was in business longer than me. They were there before I started. Unfortunately, they recently closed up. I liked those guys. They were a good company and I admired them.

In addition to my experience, I think that one of my biggest advantages is that I am a lifelong shooter…I am a shooter and I train a lot. and I’m not talking about just going to the range and target practicing. It’s tactical training. I’d say I have a few thousand hours’ worth of certificates in a box somewhere, in addition to military training and whatnot.

“You get the distilled experience…”

I am also very open to feedback from my clients. So, what you get from us, is not just experience from myself and my team, but you get the distilled experience of literally thousands of clients from all over the country going back over 20 years, where I take their criticism and their feedback to heart and it gets distilled into our product.

I’ve made pretty much every mistake out there and I know how to not make them again. If they do happen, I know how to fix it. I’m also a craftsman…I have a bit of an artistic eye and I am always looking at things critically. I want to make sure that what we do looks nice and professional, so that when you get it out of the box, it is something you can be proud of and admire, in addition to trusting to hard use.

Boresight Solutions – Gun guys vs. Marketing Guys

In this industry, I’ve found that the most successful ones that are making it are two types: there are companies like mine that are run by gun guys, craftsmen, and shooters who eat, breathe and sleep this stuff like I do.

The other type of company that is very successful is the marketing company that build guns. They know how to catch people’s eye and attract attention through a lot of superficial stuff.

Q: At this point, Boresight Solutions is more than just you, correct? If that’s the case, how do you train up your staff to do this kind of work?

Ben Simonson, Boresight Solutions – We’re a staff of full-time professionals. This is not something I do out of my garage. (laughs). Now, I started in my garage, so I’m definitely not looking down on someone who does that, but me and my guys are full-time. My guys are very well trained…I train them 40 hours a week for three months, paying them to learn, before they ever touch a customer’s gun.

They all do 7-10 guns from our inventory before they ever touch a customer’s gun, and then I turn them loose. We’re full-time, dedicated, and we love what we do. We’ve been here for quite a while and we intend to stick around. I don’t look at this as a “side thing” or a temporary thing. This is how I choose to make my living and I don’t want to do anything else.

Q: I will say…your guns seem to really resonate quality and thoughtfulness, almost at a gut level…in the same way a Winkler knife or something does.

Ben Simonson, Boresight Solutions – I’m big on esthetics. When I look at something, I can’t necessarily explain it or quantify it, but yes, it’s something that registers with me at a gut level. To me, it’s either right or wrong. I’m that way with cars, clothes, guns, home design…whatever.

When I build guns, one of the biggest compliments someone can pay me is “Oh man, this looks like it came from the factory.” I love that because I don’t want what we do to be flashy. We want it to just instinctively register that it’s done right. That goes with what so many of our customers want…something that is not gaudy, flashy, but is high quality, performance driven, experience-based, but certainly not “in-your-face.”

Q: Finally, can you talk about your pricing?

Ben Simonson, Boresight Solutions – If you’re the kind of guy that likes to skip around, get something, play with it for a while, and then get rid of it and move on to something else, our work may not be for you, even though there is a lot of demand on the secondary market. If you did go to sell it, odds are someone will want it.

However, if you are looking for something that you are going to have by your side, in your holster, all the time, and you’re going to use it, run it hard, and shoot and train with it, it pays to go with something that is built for hard use. It’s built for the fight.

It’s built for that “worst day” scenario that you hope never comes…but if it does, we don’t want our stuff to let you down. We don’t want ours to be the weak link in your chain of training, mindset, physical fitness and determination.

It’s not cheap, but for the price you get a lot of experience, and a company that stands behind its work. We’re here for our clients well after the fact. Our client is the savvy shooter who shoots, who trains, who knows the difference.

We can’t compete with the marketing companies who have big budgets and spread free guns around like candy to buy that recognition. Nor do I care to. Today, we get most of our business by word-of-mouth through the training and shooting community…guys like Scott Jedlinksi.

We expect our clients to run and shoot these guns hard. Finally, one of the intangibles of the price you pay upfront is that if you wear that texture out over a lot of shooting, to where our grip texture is not as effective as it used to be…send it back and we will retexture it for free. While I can’t detail everything, I want to stress that we do a lot more for clients above and beyond just building them a gun.

###

11 - 11Shares