In an industry where it sometimes seems that we’ve seen it all, something as familiar as a suppressor rarely elicits a double-take, but such is the case for the suppressors, rifles, and accessories of X2 Development Group. We recently sat down with Ernie Bray, the company’s founder, to discuss his innovations and what inspires him to think outside-the-box.

Q: Ernie, thanks for being willing to chat with us about X2 Development Group. Your designs are all quite striking. Can we start with how you started in the industry and how that’s lead to X2 Development Group?

Ernie Bray, X2 Development Group – X2 Development Group goes back to 2010, but I’ve been doing gunsmithing for over 30 years. I’ve also done a lot of other things to make a living. For a long time, I did gun work on the side, for friends and family. However, in 2010, I started a company, Red Creek Tactical, doing custom guns and Cerakote work. On the gun side, I was fortunate to know a lot of master gunsmiths and was able to learn from them.

Prior to that, in around 2003-2004, I also had helped some friends with an ammunition company. They were doing specialized ammunition and wanted to be able to work with the military, and I happened to have some really good contacts. I was able to assist them in eventually getting contracts with Crane Naval Surface Warfare Center.

In addition to that, I was a consultant for Barnes bullets, and helped them launch their law enforcement/military line. During that timeframe, I was also instrumental in the development of the 5.56 “optimized round.” During the development, I really started focusing on the AR platform.

In our work, a problem we faced was getting flash down and lethality up. We had to optimize lethality, accuracy, function, flash, and we did a lot with St. Marks Powder to get flash down in the 10.5” barrels, but we still noticed we were getting a lot of flash out of the receiver. In examining high-speed video, we saw that our problems were due to a timing issue. To me, it indicated a need that to be addressed, and it also turned out to be the catalyst for what X2 Development does today, although I didn’t know it at the time.

Q: Can you describe what you mean by a timing issue?

Ernie Bray, X2 Development Group – Timing in the AR platform is something not well understood or really addressed. Most gun manufacturers or assemblers have absolutely no clue on tuning and timing, or how you put together a gun and make it run reliably, clean, and not break. There are things you can do, but you first have to understand what the formula is to do so.

Semi-autos run on gas and springs, but there is a third component – mass. Springs, gas, mass, in that order. Knowing that formula, you can take any gun – direct impingement, short stoke piston, long stroke piston – and get it perfectly timed. That means that it is going to run cleaner, more reliably.

A properly tuned gun is going to eject clean cases at 4-o-clock. The better it’s tuned, the tighter that 4-o-clock ejection pattern is going to be. If you’re doing multiples and things like that, you should be able to put 8 or 9 out of 10 clean cases in a small box. If you’re spraying brass in a 10-foot pattern, it means your gun is really poorly timed, and it’s never going to run right, no matter what mythical, magical thing that you add. People will think to go with a heavier buffer, but without an understanding of what weight does. I found myself working with Alan Duggar down at Tactical Springs, and we had a lot of stuff that we published about 4-o-clock ejection, and how to get guns properly timed.

Because of this work, opportunities began opening up. I started to get invited out to Fort Bragg and other places to teach about tuning and timing. From those relationships, I started working on more gun stuff. In some of those sessions, in between classes, we’d have informal conversations with assault team guys about things that were needed. In these conversations discussing needs, I started to feel that the industry, to a large degree, has failed them. While that might sound harsh, I think that there is a disconnect in realizing what the possibilities are. I think we owe it to these folks to think more outside of the box.

Q: Is this how your muzzle device and suppressor designed originated? They certainly appear to be quite unique.

Ernie Bray, X2 Development Group – A lot of times, the end user isn’t going to tell you what they need. This because they don’t know what can be done, or what’s possible. It’s just like when I first started developing my muzzle devices. I took the idea to several Aerospace machine shops, and they laughed at me.

They laughed at me and told me “Good luck, you can’t make that. You can’t get there from here.” If I wasn’t just stupid enough to never quit, I don’t know where I’d be. (laughs). Looking back, I believe I was asking the right questions, but to the wrong people. I started talking to machine tool manufacturers and asking if what I wanted could be made.

I tell you all of this to say that what has gotten me to where I am is asking the right people, and listening, caring, and actually giving a damn. It’s understanding what guys need and being absolutely determined to figure it out for them.

Q. Let’s start with your muzzle device and then work our way towards your line of suppressors.

Ernie Bray, X2 Development Group – The first item I worked on was our muzzle device. This is something that I was asked to work on that was a muzzle brake but not a muzzle brake, if that makes sense. With a standard muzzle brake, the blast overpressure and side blast are horrendous. Combine that with the amount of muzzle flash, and these things are just not practical to use. I wanted to create something with recoil reduction, blast diversion, and really good flash suppression.

In my research, the existing consensus was you could not have something that’s both a flash hider and a muzzle brake in one device. It simply wouldn’t work. I decided my approach should be to go back to the fundamentals of why they said it wouldn’t work, who said it, and was it based on sound science and physics.

I realized that all muzzle brakes to date rely on something called “simple flow.” Gas exits the muzzle and hits a forward baffle, compresses against it, creating significant added blast overpressure and highly elevated sound pressure levels. Research from the University of Florida-Gainesville audiology department indicates that muzzle brakes can literally raise decibels into the 200-range. So even with doubled-up hearing protection, you’re sustaining significant hearing damage.

Q: I’m familiar with the fact that brakes are loud, but can you talk a bit more about blast overpressure?

Ernie Bray, X2 Development Group – Yes, when you use a standard muzzle brake, there’s the issue of dangerous blast overpressure. That’s been studied for about the last 15-20 years. Only in the last year, has the military come out and said they recognized PTSD as physiological not psychological, and it is due to cumulative traumatic brain injury – and cumulative traumatic brain injury is due to these lower levels of blast overpressure – basically from small arms fire.

The consumer market is kind of oblivious to this, but any blast overpressure over 12 PSI can cause cumulative traumatic brain injury. An A2 flash hider on a 10.5” Mk18 is basically in the 13-14 range. That’s with an A2. Now, if you put a muzzle brake on it, you can double or triple that. So, I see muzzle brakes as dangerous to the end user. With that being the case, how do you come up with something that does everything? The answer, as it turns out, is “complex flow” instead of “simple flow.”

With complex flow, you’re looking at pressure zones, and the amount of gas acted on by the device. For example, a typical muzzle brake acts on about 40 percent of the gasses, whereas our Vent Forward Muzzle Brake acts on about 90 percent. We’re moving the gasses through forward bypasses, then introducing a tremendous amount of microstructures that forces gasses to repeatedly expand and compress. Every time the gas recompresses, it creates forward thrust. So, you’re not going to get as much recoil mitigation as these offensive, hardcore brakes, but what you do get is a wonderfully balanced design unlike anything else out there, that is very safe to shoot.

I have videos of guys shooting even 10” guns right off my shoulder, right at my nose, without doubled up hearing protection. Again, this is because we are breaking down the blast overpressure from one zone into a bunch of much smaller zones, and then safely directing it forward. You get good recoil reduction, flash suppression, muzzle neutral, with blast diversion in one device.

Q: Let’s talk about your suppressors…

Ernie Bray, X2 Development Group – While designing the Vent Forward Muzzle Brake, I started looking at suppressors, and I quickly realized that few, aside from exceptions like Lawrence Livermore National Labs and what Russ Oliver was trying to do at OSS – he didn’t quite get there but he was trying – were trying to significantly improve flow dynamics in suppressors. I knew I wanted to make something that had zero backpressure, did not impact reliability, and was cleaner and quieter. In the end, we were able to do that.

To be very honest, there’s a lot of hype and hyperbole in suppressors. The fanboys of this brand or that brand too often focus solely on decibels. There’s a fixation on sound that ignores other important things that a suppressor should do. The number of people that really understand suppressor flow dynamics in this country, honestly, I think I could count them on one hand. Two guys at Lawrence Livermore, one guy at Oak Ridge National Laboratory, and a couple of others. That’s it.

In addition to not considering flow dynamics, I too often see people not considering the firearm the suppressor is attached to. For example, I’ll see pseudo-expert audio engineers testing and rating suppressors affixed to 20” barreled bolt actions. The problem with testing and rating suppressors like that is those guns are closed systems. The exit pressures are low. The amount of unburnt powder is low.

So, if you take a suppressor that “expert” claim to be the best because it is the “quietest” and put it on my 8” Draco, well that gun has very high exit pressures and a lot more unburned powder. It’s also a long-stroke piston system and the gas take off is right at the end of the barrel. Whatever happens in that first 2.5 microseconds in that suppressor will negatively impact that operating system. Backpressure and sound are both relevant to the individual weapon system you are running it on. You can’t get away from that fact, as much as some would ignore it.

On a long-stoke piston system, the gas is going to go up in that piston tube and cause a massive overpressure there. Your peak sound ends up coming out of that piston tube, and not the end of the suppressor. It’s also going to drive that long-stoke piston system hard. On a DI gun, that gas has a longer way to travel, so it’s going to be affected differently. The point is, there is no ‘one size fits all.’

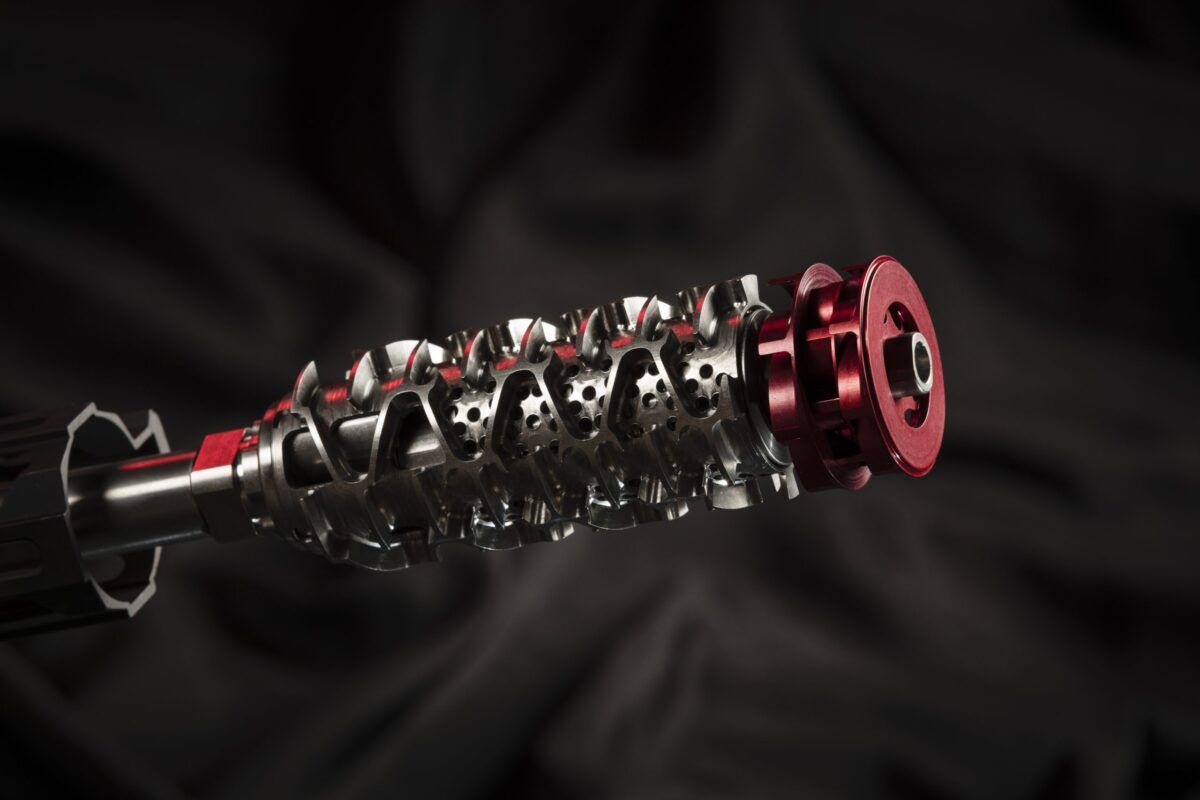

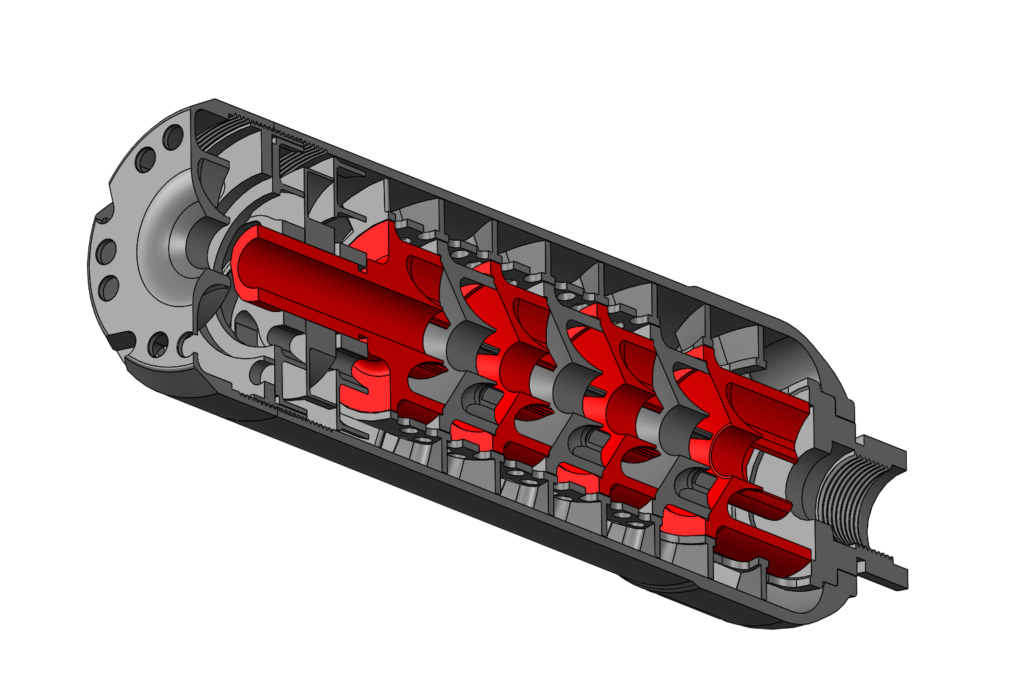

In realizing this, I took a very different approach to suppressor design. What we’re creating is something that is truly state of the art. Firstly, what I did with my design was to make it not welded. It’s all CNC-machined, not 3D printed. It’s highly modular, fully user serviceable, and highly configurable, so that you can take the suppressor and divide it into two even parts.

In that first part, in the first 2.5 microseconds, I focus on the initial blow down. I need to have a certain rate of pressure blow down for a certain weapon system so that I don’t experience backpressure, or if I do, it’s only a small amount. Now, afterwards, if I want it to be quiet, in the latter half of the suppressor, I can then focus on gas clamping…

In my PowerPoints I do for the military, the first slide says, “make the gas your bitch.” Well, just how do you do that? How do you get the gas to flow where you want it to flow? How are you going to pressure balance it? How and where are you doing gas clamping? Making the gas do exactly what you need it to do means being able to alter flow dynamics. For example, creating a prolonged microsecond plug in the suppressor’s core, that forces the gasses to go into the coax/bypass chambers.

All of this is to say that I really thought it through when it came to our suppressor. I did my research. I looked at what makes a difference, and how you would design them to function and get away from the hype and hyperbole, basing what I did on science, not bullshit. That meant really understanding flow dynamics and how to get gasses to go where I really wanted them to go.

When I look at what is really needed by those who put themselves in harms’ way, and what are the true priorities are when it comes to suppression, well, what is it they truly want? They want zero back pressure. The Quantum Flo Technology incorporated in the Orion X suppressor prevents over gassing and reduces recoil better than standard baffle designs. They want no change in the weapon’s operational reliability. Flash suppression is next. They want a point-of-impact shift that is minimal and repeatable. Thermal signature, sound signature, smoke signature come next.

One program manager with Crane NSWC commented “on the list of importance, frankly sound is at the bottom of the list.” On the consumer market, this is sacrilege…But for others, if their guns don’t work, if there is a big ball of flame coming out of the front, or if there is a massive point-of-impact shift, they simply don’t care how quiet it is.

Q: Anything else you’d like to add?

Ernie Bray, X2 Development Group – The goal with our suppressors was to listen, answer their needs, and then focus at the end on making it as quiet as we could…Can I do all that and make it quiet? Yes, we can, and I have proven that and achieved that. We’ve created a quieter running suppressor that has none of the limitations or drawbacks of other designs. They prevent over gassing and reduce recoil better than standard baffle designs. I know it’s a bold claim, but I think we’re making the best suppressor available anywhere today.

###