In part two of our recent discussion with Chad Albrecht at School of the American Rifle, we discuss common questions about AR lower receivers, why gauging matters, and what to consider before purchasing a budget AR lower.

In case you missed part one of this recent conversation earlier this week, click here to read about Chad’s recent AR Master Build Class, and his ideas on simple and inexpensive ways that builders can improve their chances of success when putting together a budget build.

ARBuildJunkie is blessed to have Chad as a resource to be able to ask occasional questions to. We’re tremendously grateful for his generosity and willingness to share information with our readers. To learn more about him and his School of the American rifle, please be sure to check out our feature interview with him…or other more recent articles which you can find here:

- Common AR-15 Myths – School of the American Rifle

- AR-15 Gas System Issues – School of the American Rifle

- Headspace Gauge & the AR – School of the American Rifle

- AR-15 Feed Ramp Problems – School of the American Rifle

Also, please consider supporting Chad by following School of the American Rifle on Facebook, or via the Instagram.

Q: Let’s talk about the idea that AR lower receivers are all the same. It’s something I hear quite a bit online and on forums. Can you give us your perspective on that?

Chad Albrecht, School of the American Rifle: The first argument that a lot of people use who lean more towards the more budget-friendly builds is they say “this AR lower receiver that I purchased from so and so has the same forge marks as one that is made by Colt, so, therefore, they are the same.”

My counter-argument to that is that just because the material the AR lower receiver was forged out of at a location was the same, that does not mean the machines that made the product, and the processes used to finish the product are of the same quality.

While a Colt AR lower receiver might not be flashy looking and may not have the roll marks that someone is looking for, or have a perfect finish, generally when I gauge them out, they fall within spec of what I am looking for. That can be the hammer and trigger holes, or where the buffer tube screws into the receiver extension….all the holes, all the dimensions, everything lines up.

Guaging Budget vs. Premium AR Lower Receivers

I’ve seen lots of cheaper stuff gauge out just fine. In the 18-hour course that we just went through, I tell students to bring more than one lower due to the problems that I encounter and the constant issues I see. Because of that, students were bringing four and five AR lower receivers to class. They only built out one gun, but we did gauge every lower that they brought. What was surprising was that some of the very expensive lowers that they brought…they were “hogged out” to use a non-technical term. Another way to describe it is “the holes were too large.”

In the rear area where the buffer tube screws in, or the receive extension screws in, the tapped out hole was larger than it should be, and it will take a no-go thread gauge. The fire control group holes were larger than they should be, so people insist on buying anti-rotation pins because the holes are pretty large from the factory. Sometimes the holes are too small, so people end up banging on the hammer and trigger pins.

“Trying to be as thorough as possible”

You don’t necessarily need gauges on a one-off basis, but if you are trying to be as thorough as possible and eliminate any guesswork, I turn to the gauges, but I do show people ways to look for those things without them. In the end, I want the parts to fit and not be too sloppy .

Parts shouldn’t have to be hammered together they should go together…and then make sure that when things go together, the tolerances are not so sloppy that things will fall apart.

Q: A lot of folks notice when something is too tight, but too loose is an area that can be easy to ignore…

Chad Albrecht, School of the American Rifle: Going back to the buffer tube, there are three areas there that have to interface. You have the buffer tube/receiver extension, you have the lower receiver where it is threaded to accept that, and then you have the castle nut. All three of those parts have to fall within a certain range if you want them to stay put.

The proper way is to lubricate those things, torque those things to a proper spec, and then stake that castle nut so it doesn’t move. However, if you have things that are really sloppy, sometimes the staking itself does not hold if you are really rough on the gun.

That blows people’s minds because they think the staking should be sufficient. It’s the bare minimum. It does not mean that if you stake it and the parts are really sloppy, that it is going to hold. This is where gauges come into play…or pre-assembly so that you can get a good feel for it.

If you can put your castle nut on your buffer tube and when you shake it, you can hear a rattling like it’s some sort of children’s toy, you probably have an interface issue, whether it being the castle nut being too large or your receiver is out of spec.

Q: When you’re gauging an AR lower receiver, what are some things you are you looking for that people overlook?

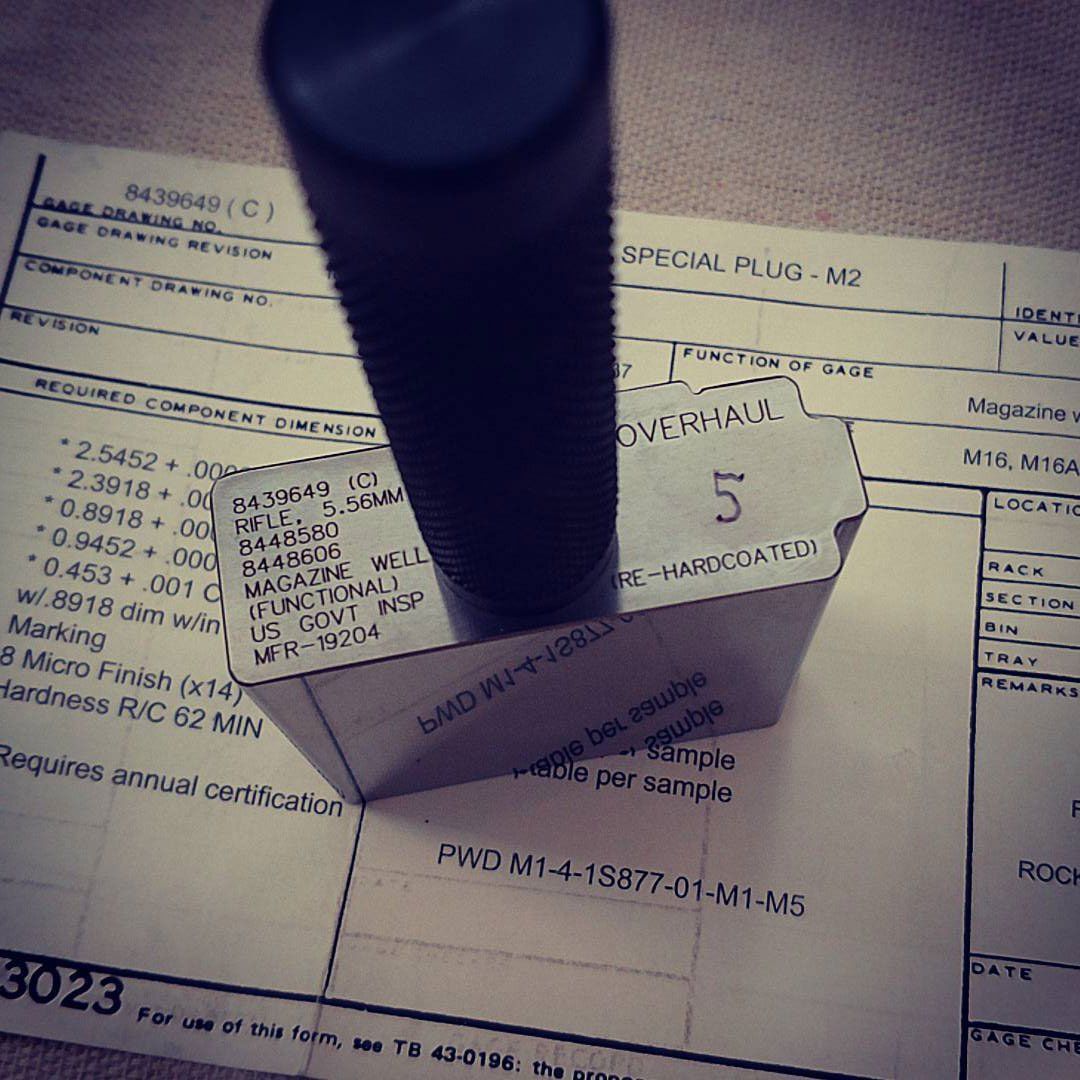

Chad Albrecht, School of the American Rifle: Some of the gauges that I use are U.S. government gauges, some are copies of those gauges that I use. I do that because some of the gauges are somewhat rare and collectible. Since they are not in abundant supply, I usually make copies of those… the ones that are rare, I am the only one who uses them so that someone else does not mess them up.

That’s something that people don’t realize about gauges – you can’t use them forever. They periodically have to be checked to make sure it has not fallen out of range. You have to make sure it is still accurate.

One of the first gauges that I use is a magazine well gauge. It’s a gauge that tells me if the magazine well is too tight. It’s basically a go-gauge. If it won’t go in, that tells me the lower receiver is going to be sensitive to certain magazines. This reminds me of something that I tell my students…it’s the idea of “magazine diversity.”

I tell them not to put all their stock in just one type of magazine. If you see a magazine that you think looks cool because it’s on Instagram, or all your buddies tell you that a certain magazine is great…well, if you buy just those magazines, that particular brand may not work with your gun. Your lower might fall into a range where it just does not like those mags. Maybe it likes the mags, but they just don’t drop free properly.

Q: I’m actually not too familiar with a magazine gauge, is this something that is readily available on the market?

Chad Albrecht, School of the American Rifle: People see this gauge and want to know where they can get one. Well, you can’t. They’re highly collectible. Because of that, I show my students how they can work around that. They can do this by simply trying a handful of different magazines. They can try a Government Issue aluminum mag, try Magpul P-Mags from various generations, try a Lancer mag. Just go through and try everything you can.

Then after that, go to the range. At the range, I tell people it’s a wise idea to number their magazines. If you have a malfunction, make a note. “Hey, magazine number 6 from Magpul gave me a problem.” As you keep shooting, and you don’t have any more problems until you use that magazine again, you might have a helpful realization that maybe it’s not the gun that has a problem.

This approach helps a shooter understand that some magazines can be sensitive in some guns, and it helps me tell people how to troubleshoot. That’s one of things that people get the most frustrated about when they are trying to figure out a problem.

“It’s hard to pinpoint where the problem happened”

They build a gun out of a bunch of parts, but when they have a problem, it’s hard to pinpoint where the problem happened. Now , If you have a factory gun that had absolutely no problems at all, and then you installed an aftermarket bolt catch, and started having issues where the gun was having failure to lock issues after the last round, you could safely with some authority say that “hey, I think my problem is that magazine catch.”

Q: From a broad, somewhat similar perspective, it seems like all the gauging you recommend can also help you isolate issues…

Chad Albrecht, School of the American Rifle: I think there’s truth to that. When you throw a bunch of parts into the gun at once, you need to be able to sit back and be calm, and take an intelligent look at the situation. That’s certainly something the gauges help with.

Using gauges does not mean I am not going to have issues with the gun, but it diminishes the probability of having a problem because I know that this part fit properly with that part, and this part properly interfaced with that part. It allows me to troubleshoot things before they even pop up in the build.

Q: Going back to magazine issues, I have had some experience where a simple Cerakote job made life more difficult…

Chad Albrecht, School of the American Rifle: A magazine gauge is great in a situation like that because it tells you that your lower is not going to be magazine sensitive, and it will accept most magazines. Some guys like to paint their guns, do water transfer finishes on them or Cerakote them like you did, and in a lot of cases when you do something like that, you’re changing the dimensions on some really important parts of the gun. They get a bunch of finish inside the hammer and trigger holes, inside of the magazine well, and things stop working right after that…

The reason that Cerakoters do that is because if they were to send a parts kit that was Cerakoted back to the customer with parts that were not finished…let’s say the holes where the parts go in were not finished and were still black because it didn’t get finished, they’d be accused of cutting corners. But if it was me getting my gun Cerakoted, I’d want that. I’d want them to mask off critical operating surfaces of my AR lower receiver. I wouldn’t want those areas finished.

It’s one of those things that people really don’t know. They are more looking at appearance than function. But because function is key, it’s important that we check all of those holes, we check the magazine well, we check where the buffer tube screws in, and anywhere that we find something that is sloppy or too small, we try to address them.

Q: Not becoming enamored with appearance versus function is a good lesson. What about price versus quality? You may have touched on it when we discussed all AR lower receivers being the same, but where do you stand on that issue?

Chad Albrecht, School of the American Rifle: Some parts like AR lower receivers simply cost more than others. Some companies, based on what I’ve seen, honestly do charge more just because their stuff is flashy or they have more name recognition. Some companies also charge more because of quality control. Bravo Company is one of those that I can say unequivocally that is insane, in a good way when it comes to gauging.

They go beyond what almost all other companies do. It’s amazing…and you’re paying for that. You’re paying for a company to pay a person who is very thorough to go through and check things…just like you’d do in one of my Master Build classes. So, in the end, the likelihood of you having a problem is diminished.

Q: “Diminished” is an important word there…

Chad Albrecht, School of the American Rifle: It is, and I say that because the downside of that is, let’s say you are buying a quality bolt carrier group from Bravo Company…that does not mean it is going to interface properly with the barrel you have selected from another manufacturer. It all depends on how those two parts marry.

But the quality control, from what I’ve seen, costs money. It costs because they have to be very thorough and they have to be paid a fare wage to do that.

If you’re going to pay someone to be a perfectionist, you’re going to have to pay them accordingly. It’s a very mundane job for the people that do that, but they’re very good at what they do. They’re constantly checking, cross checking, making sure that all their work is up to task.

The cheaper companies will not do that, and to try to pass that savings on to the customer. But the customer is actually absorbing the cost themselves if they have to troubleshoot or fix things. The counter-argument to that is that if that company has a good warranty, you can just call them and they’ll replace the part. That might very well be the case.

“how much money am I willing to save?”

Personally, I would ultimately like to avoid that problem, but that’s really something for each end-user to decide. Consumers have to ask “am I willing to be the quality control guy, and how much money am I willing to save before that might become a real headache that I cannot figure out and I am going to have to pay someone to have to figure it out.”

Now, let’s say you do have to take it somewhere. What’s to say the local gunsmith has any more abilities than you do when it comes to fixing the problem? They really don’t.

Q: That’s a good incentive to look into taking one of your classes, right?

Chad Albrecht, School of the American Rifle: Well, it’s certainly something I try to convey in my classes. My classes are not necessarily going to make you a master AR builder. It’s not going to make you an armorer or a gunsmith…but what it will do, it will arm you with enough knowledge so that when you walk into a shop and you’re looking for something to get done, you can ask questions, and based on how that person responds or the tooling that person has, you can make an informed decision on if the person is capable of doing the work to the standard that it should be done to.

###

Chad is an absolute treasure trove of info. I learn so much every time I read or watch something he puts out.