So, you read part one of this series and have decided you are either going to begin building an AR-15 or make an attempt to modify your current setup. While building an AR-15 might seem straightforward, that is not always the case.

Despite what you might have been lead to believe, building an AR-15 isn’t like building Legos. How do you know when you should attempt to do something yourself versus reaching out to a professional to do the work for you?

Pushing past your comfort level and making a mistake with your build is very avoidable. You should know the limits of your capabilities. Let’s say you decide to have someone else do the work for you. How do you know they are qualified to do the work properly? There’s a chance the expert you’re reaching out to may not be what he claims to be. In both cases, the problem causing the issue for the builder of that AR is ego.

Working on your own guns can be a richly rewarding experience. Not only are you customizing things to meet your unique preferences and needs, but you are getting a sense of accomplishment by doing it yourself.

Many upgrades on the AR platform can be completed with a few of the basic tools inherent to the platform. Be sure to check the previous article for a few examples or if you need more help, drop a comment below. Are you changing out a grip? No problem, you just need a screwdriver or Allen key, depending on the screw.

Changing out a buffer and spring requires only a means of depressing the retainer. Are you swapping out your trigger and hammer? Thats not too tricky. Simply find the right punch to drive out the pins holding them in place, and you should be good to go.

Dirty Bird 2-Stage Trigger Group

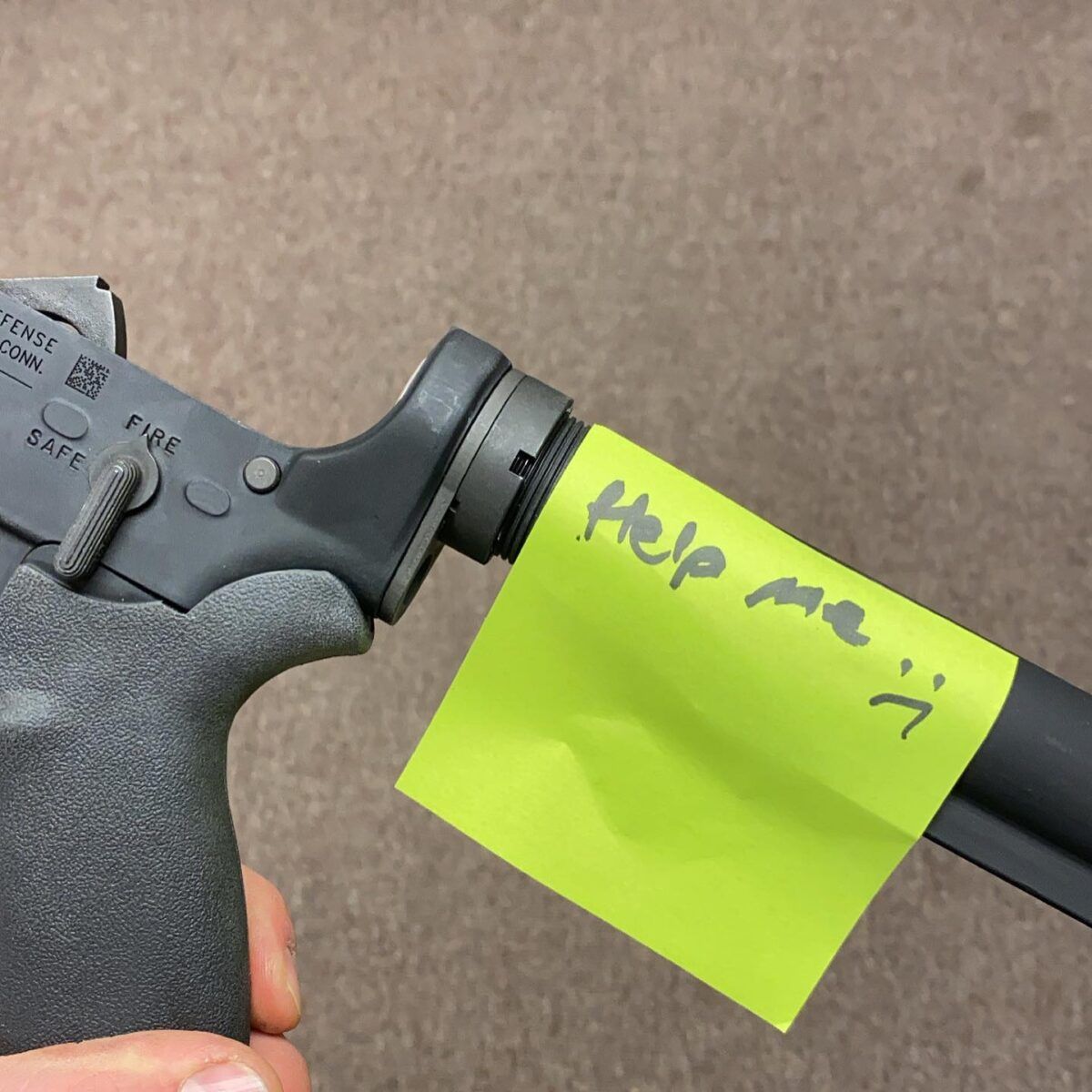

What if you lack the proper tools or the skills to do the work, though? Let’s face it, not all of us are mechanically inclined, and there is no shame in that. Shooting is a different skill set than working on guns. Perhaps you purchased a factory rifle and didn’t allocate funds for tools when you decided to swap out some parts. Whatever the case may be, chances are if you own an AR, there will be a point in time when you need help doing the work.

Building an AR-15 – Don’t Fall Victim to an Oversized Ego

For whatever reason, ego leads people to attempt things beyond them. Work ends up being done in a haphazard fashion, and the result is something potentially dangerous. Remember, we are containing explosions inches from our faces with firearms. Why risk something going wrong by “just sending it” just so your ego doesn’t take a hit.

How do you know when to seek out help? This will vary a bit from person to person, but the goal here is to avoid stumbling into things that will get you in over your head. This could mean that when attempting to thread on a muzzle device or install a screw, you stop to avoid cross-threading if something doesn’t feel right.

Maybe you are trying to torque down a castle nut and see the wrench notches deforming because you lack the proper tool. Or the step that most hobbyists (and some “gunsmiths”) have an issue with – installing the pivot pin while capturing the detent and spring.

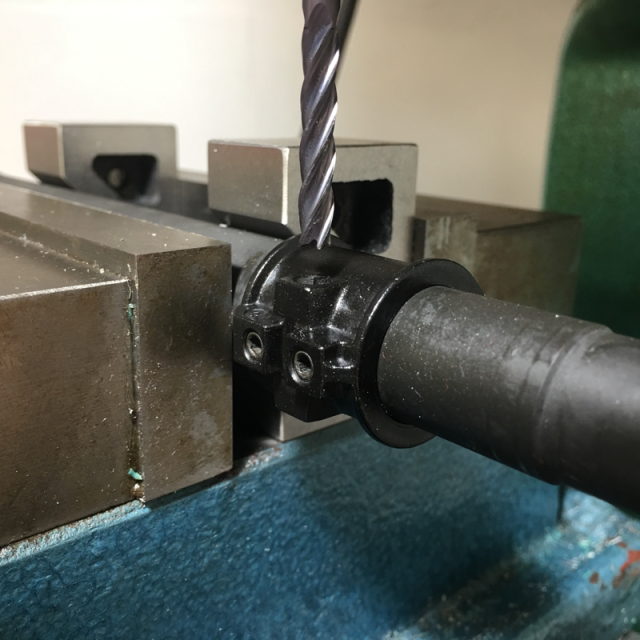

Speaking generally, it is my experience that anything beyond your skill level or requiring specialized tools or machining should be outsourced to a professional. A great example of work you are probably better off paying someone to do is a pin and weld. The process seems simple enough, you drill partway into a muzzle device and barrel to apply a pin, then weld over it so the muzzle device is permanently attached.

What sounds doable in concept can quickly become a nightmare for the uninitiated. For instance, would you know how far to drill? Without the proper knowledge on plunging a drill bit to depth, you could end up with an unintended barrel port and an alteration of the entire gas system of your AR.

These sorts of mistakes are more common than you might think. They are also costly lessons, as you’re stuck replacing the parts and sending the work to be done, not to mention the time you are without a useable gun.

Building an AR-15 – Seeking a Professional

So, you might ask, “what are some specific instances where I should consider seeking assistance? There are many services I would recommend the average gun owner send out to have done. Lapping receivers, repairing threads, adding, changing barrel tapers, pinning gas blocks, drilling, and tapping and changing dimensions are all examples of services best left to professionals.

These processes typically involve machining in some form or another. Unless you have the technical skill and some expensive shop machinery, you aren’t likely to be able to do the job correctly and to the same degree of precision.

Additionally, things happen from time to time. For example, tools can break off inside (especially when working with small diameter tools and holes). Mistakes can be made, and if a professional is working on them, it is on their dime to have them fixed.

Building an AR-15 – Vetting a Professional

Vetting the people that work on your guns is VERY important. The internet is filled with stories of “gunsmiths” botching jobs they shouldn’t have ever taken in the first place and then the ensuing nightmare of trying to get them to make it right.

Anyone that has worked on guns for a living has messed something up for a customer. The key is how the person or shop responds to their mistake. I personally have had to replace components out of my pocket when I’ve messed something up, and rightfully so. There is no excuse for a customer to be told that a mistake will not be made right to the customer’s satisfaction (within reason).

So how can you tell who should be trusted to do the work for you? The best tool to vet someone before letting them work on your guns is a solid knowledge base. Visit the shop you are interested in and do an assessment. Ask if they’ve done similar work before.

Politely ask to see any examples they might have, and ask how they measure things or what they compare their work against. It would be wise to see if they know what the proper specs/tolerances are by talking to them. Also, use the visit to see what sort of vibe their customer service team or smith gives off.

Communication Matters

Communication is another excellent tool for gauging if a shop is the right fit for you. Ask what their lead times are and how often they update customers if those times need to change. If the shop is not local, ask how they want items sent in and how they send them back. If they can’t give you a response detailing preferred shipping methods or their plan/policies to send completed work back, is their level of care going into the work itself going to be any different?

Keep in mind that communication goes both ways. When you decide to send work off, communicate what you need done ahead of time. If you are sending in an upper and need the muzzle device clocked a certain way, tell them. If there are multiple variations of a part and you want a certain one used, it needs to be stated ahead of time. Do yourself and the person working on your gun the favor of having clearly defined needs, and if you aren’t sure about something, ask. Those working on guns professionally genuinely want you to be happy with the result if it is realistic.

Lastly, look them up online, but understand how to sort legitimate negative reviews from people that didn’t get their way. There will always be instances where someone is left less-than-thrilled with an interaction, and other times where people leave negative feedback to be spiteful.

Look for anything bashing the shop to have pictures and/or a detailed write-up of the work that led to the comment. Similarly, in positive praise, look for more meaningful content than one-liners. If someone were genuinely impressed with the work done, they would be typing more than “This shop rules.” Look for specific examples of the work you are looking to have done and see what the responses in that scope are. Ask about shops on message boards or in Facebook groups but apply the same filters for bitter responses versus actual reasons to be wary.

While a quality shop can perform some amazing feats, there are limits. You need to understand that some things are either not possible or not realistic (even if they can be achieved). There will be times a shop tells you that they can’t do the work you are asking for and may recommend another shop or ask you to contact the manufacturer to have them help. For example, if a company pins a front sight block onto a barrel crooked, there is only so much that can be done to correct it, and it is more realistic to send it back for replacement with a properly pinned block.

If you buy a brand-new barrel and the rifling is damaged or not there, you might be told to send it in for replacement, as cutting rifling is something most shops will shy away from. A shop telling you that they aren’t the right fit for the job should be viewed as a sign of integrity and pride in their work, not as snubbing you.

At the end of the day, as the owner of a firearm, you owe yourself the best level of care and service to that firearm. Whether that means realizing the work you need is beyond your skillset or turning down a shop offering to do the work for you.

Would you take your car to a mechanic that didn’t work on that make or model? Would you trust someone to do an engine swap in his garage because he told you he knew what he was doing? Would you throw your car up on some cinderblocks to change your rotors?

Do yourself the favor of doing things right the first time and not having to fix mistakes that could be avoided.

###

What I have found surprising is the actual lack of knowledge many older gunsmiths have about the AR-15 platform. Many gunsmiths have the belief the AR platform is a lego set not worthy of their talents and then blame any failures that occur on poor QC of the parts they used or the rifle design was flawed from the start..